In the rapidly evolving automotive industry, efficiency and performance are at the forefront of innovation, with cutting-edge technologies significantly pushing the boundaries of what's possible. One of the standout advancements in this arena is the use of Fuel Cells Silicone Hose. According to Dr. Emily Chen, an expert in automotive energy systems, "The integration of Fuel Cells Silicone Hose not only enhances the performance of fuel cell vehicles but also plays a crucial role in ensuring their reliability and durability under various operating conditions."

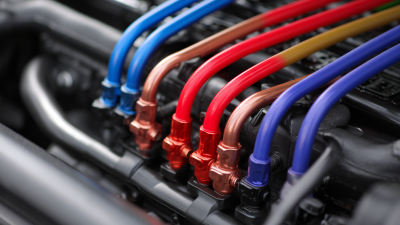

The application of Fuel Cells Silicone Hose is transforming the way fuel cell vehicles manage fluids and gases, contributing to a more efficient energy transfer system. These hoses are engineered to withstand extreme temperatures and pressures, making them essential for high-performance applications. By utilizing advanced materials and innovative designs, manufacturers are improving the overall efficiency of fuel cell technology, which is imperative for the future of sustainable automotive solutions.

As the automotive sector continues to embrace alternative energy sources, the importance of robust components like the Fuel Cells Silicone Hose cannot be overstated. As Dr. Chen notes, the reliability and efficiency of these hoses are key to achieving the ambitious goals set by the industry to reduce our carbon footprint, paving the way for a cleaner, greener automotive future.

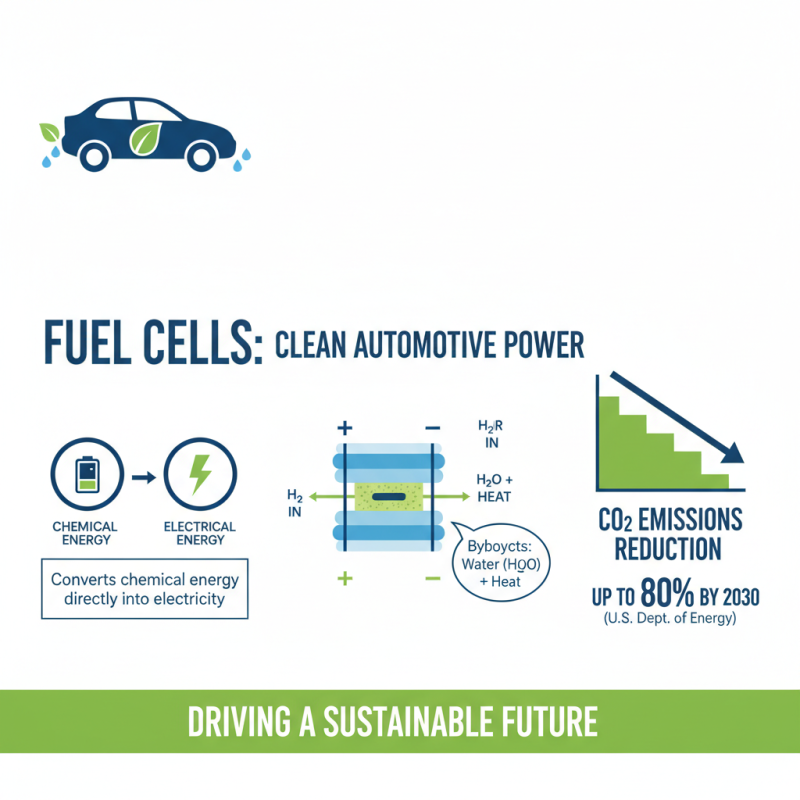

Fuel cells represent a transformative technology in the automotive sector, converting chemical energy directly into electrical energy through electrochemical reactions. Unlike traditional combustion engines, fuel cells produce water and heat as byproducts, making them an environmentally friendly alternative that significantly reduces greenhouse gas emissions. According to the U.S. Department of Energy, by 2030, fuel cell vehicles could reduce carbon dioxide emissions by up to 80%, highlighting their potential role in mitigating climate change. This shift not only promotes sustainability but also aligns with global trends towards cleaner transportation.

The integration of fuel cells in automotive technology is accompanied by advancements in components such as silicone hoses, which play a crucial role in enhancing overall system efficiency. Silicone hoses are designed to withstand high temperatures and pressures, ensuring reliable performance in fuel cell applications. A report from the Society of Automotive Engineers suggests that the use of high-performance silicone hoses can improve thermal management, thereby optimizing the energy output of fuel cells. This synergy between fuel cells and advanced materials contributes to better fuel efficiency and longer vehicle range, positioning fuel cell technology as a viable contender in the future of automotive mobility.

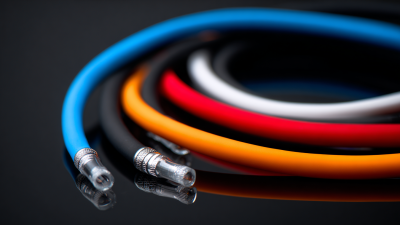

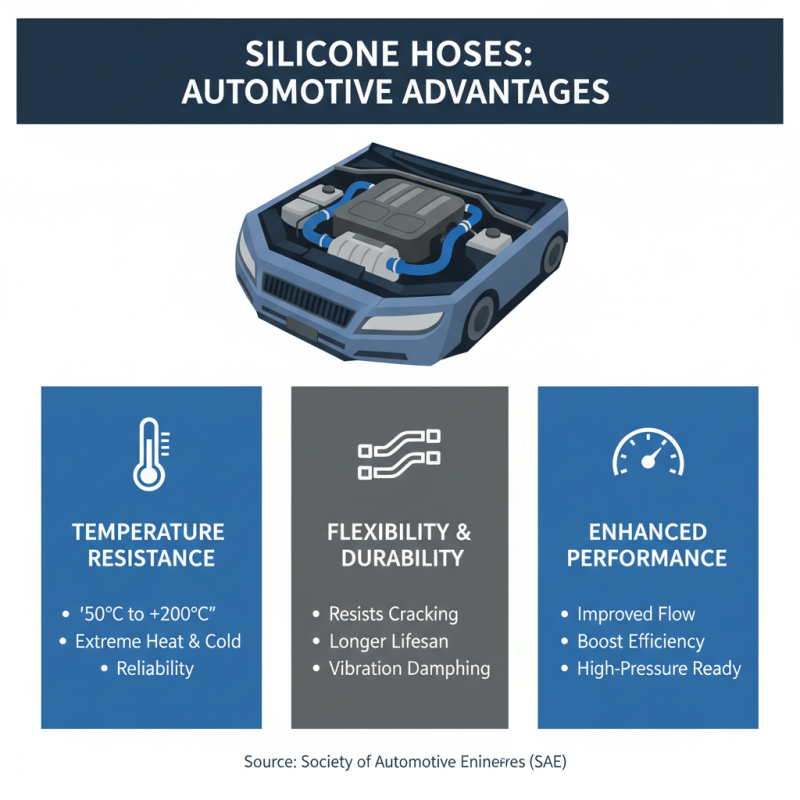

Silicone hoses have gained significant traction in the automotive industry due to their superior properties that enhance vehicle efficiency and performance. Composed primarily of silicon, oxygen, and other additives, silicone hoses exhibit outstanding temperature resistance, flexibility, and durability compared to traditional rubber hoses. Research by the Society of Automotive Engineers (SAE) indicates that silicone hoses can withstand temperatures ranging from -50°C to +200°C, making them ideal for high-performance applications where reliability is crucial.

The benefits of using silicone hoses in vehicles extend beyond temperature management. Their resistance to aging, corrosion, and chemicals allows for longevity and reduced maintenance costs, ultimately improving vehicle performance. According to a recent market analysis by Grand View Research, the automotive silicone hose market is expected to witness a CAGR of over 5% from 2021 to 2028, driven by the increasing demand for lightweight and efficient automotive components. By reducing overall vehicle weight with silicone hoses, manufacturers can optimize fuel economy without compromising on strength or integrity.

Tips: When selecting silicone hoses, ensure they comply with industry standards for quality and safety. Regular inspections for wear and tear can prevent unexpected breakdowns and extend the lifespan of your vehicle's components. Additionally, consider the specific application environment to choose the right silicone formulation, enhancing performance under varying operational conditions.

Fuel cell technology is revolutionizing the automotive industry by enhancing efficiency and performance in ways that were previously unattainable. As vehicles transition from traditional internal combustion engines to fuel cell systems, the integration of silicone hoses has become essential. These hoses, known for their durability and flexibility, play a crucial role in managing the high-pressure environments typical of fuel cell applications, ensuring optimal gas flow and temperature management.

A recent report from the International Energy Agency (IEA) highlights that fuel cell electric vehicles (FCEVs) offer a significant reduction in greenhouse gas emissions compared to conventional vehicles, achieving up to 70% lower emissions over their lifetime. Moreover, the use of silicone hoses in fuel cell applications contributes to this efficiency by providing superior thermal stability and resistance to harsh chemicals found in hydrogen fuel systems. These characteristics not only enhance the vehicle’s performance but also extend the lifespan of critical components, resulting in reduced maintenance costs and improved reliability.

Furthermore, according to a study published by the Hydrogen Council, the global market for fuel cells is expected to reach $46 billion by 2024, demonstrating a growing interest in sustainable technologies. As automotive manufacturers increasingly invest in fuel cell technology, the demand for high-performance materials like silicone hoses will continue to rise, further driving advancements in automotive efficiency. The synergy between fuel cell technology and robust materials engineering is paving the way for a cleaner, more efficient automotive future.

Silicone hoses are increasingly being utilized in automotive fuel systems, delivering significant performance improvements over traditional rubber hoses. One of the most notable advantages is their superior heat resistance. Silicone can maintain its integrity even at high temperatures, ensuring that fuel systems operate optimally without risk of degradation. This resilience minimizes the chances of leaks or failure, enhancing the overall reliability of the vehicle's performance. Furthermore, silicone’s ability to withstand a broader temperature range allows for consistent functioning in diverse operating conditions, which is essential for modern engines subjected to variable environments.

In addition to thermal stability, silicone hoses also offer enhanced flexibility and durability, which can lead to improved fuel flow. This design flexibility allows for custom shapes that can efficiently direct fuel without sharp bends, reducing turbulence and optimizing delivery. The result is an increase in fuel efficiency, as less energy is wasted during transport through the system. Additionally, the smooth interior surface of silicone hoses minimizes friction, further aiding in the effective flow of fuel. By adopting silicone hoses, automotive engineers can achieve both improved efficiency and performance in their fuel systems, contributing to overall vehicle enhancement.

The future of automotive design is increasingly intertwined with the advancement in fuel cell technologies and the innovative use of silicone hoses. As the automotive industry shifts towards sustainable energy solutions, fuel cells are gaining prominence due to their ability to convert hydrogen into electricity, resulting in emissions-free vehicles. This transition not only addresses environmental concerns but also paves the way for more efficient energy systems that can enhance vehicle performance. In this context, silicone hoses play a critical role, offering superior resistance to high temperatures and pressures, which are typical in fuel cell applications.

As technological advancements continue, we can expect the integration of fuel cells and silicone hoses to evolve significantly. Manufacturers are focusing on developing more effective cooling systems and optimizing airflow dynamics, utilizing lightweight and flexible silicone hoses that can improve overall vehicle efficiency. Furthermore, as safety regulations and performance standards tighten, silicone hoses stand out for their reliability and durability in demanding environments. This synergy between innovative materials and fuel cell technologies positions the automotive industry for a transformative shift towards cleaner, more efficient vehicles, promising a greener future for mobility.

| Benefit | Description | Impact on Automotive Efficiency | Future Prospects |

|---|---|---|---|

| Lightweight Construction | Silicone hoses are significantly lighter than traditional rubber hoses. | Reduces overall vehicle weight, improving fuel efficiency. | Increased usage in electric and hybrid vehicles. |

| High Temperature Resistance | Silicone hoses can withstand extreme temperatures without losing integrity. | Enhances performance in high-temperature engine applications. | Utilization in high-performance engines continues to rise. |

| Chemical Resistance | Resistant to various automotive fluids, including oil and coolant. | Lower maintenance costs and improved vehicle longevity. | Growing adoption in electric vehicles for fluid management. |

| Flexibility and Durability | Allows for easier routing and installation in tight spaces. | Enhances overall design capabilities and performance tuning. | Future designs may focus more on compact and efficient systems. |

| Reduced Noise and Vibration | Silicone absorbs vibrations better than other materials. | Contributes to a quieter and more comfortable ride. | Increased focus on sound dampening technology in future models. |