When it comes to enhancing vehicle performance, selecting the right components is crucial. One often-overlooked yet essential component in performance upgrades is the CAC silicone hose. These hoses are designed to withstand high pressure and temperature, making them an excellent choice for applications involving cooling and intake systems. Understanding the unique properties and benefits of CAC silicone hoses can help vehicle enthusiasts make informed decisions that align with their performance needs.

Choosing the right CAC silicone hose requires careful consideration of several factors, including the size, thickness, and overall design of the hose. The material itself is engineered to provide superior durability and flexibility, which is particularly important in high-performance scenarios. Additionally, the compatibility of the hose with existing engine configurations and the specific requirements of the vehicle's performance goals cannot be overlooked. By prioritizing these elements, drivers can ensure optimal performance and longevity of their vehicle’s systems.

In the pursuit of performance upgrades, opting for a high-quality CAC silicone hose can contribute significantly to an engine's efficiency and reliability. This article will guide you through essential aspects to consider in the selection process, ultimately assisting in making the best choice for your vehicle's performance aspirations.

Cac silicone hoses are increasingly recognized as crucial components in enhancing vehicle performance. These hoses, crafted from high-quality silicone materials, offer superior resistance to heat and pressure compared to traditional rubber hoses. According to industry reports, silicone hoses can withstand temperatures ranging from -60°C to 200°C, making them an ideal choice for high-performance applications where traditional materials may fail. The flexibility and durability of silicone also contribute to better airflow and reduced turbulence, which enhance engine efficiency and overall vehicle performance.

In addition to their thermal stability, cac silicone hoses exhibit exceptional resistance to automotive fluids and aging, which significantly reduces the risk of degradation over time. Research indicates that silicone hoses can outlast standard rubber hoses by up to three times, translating to lower maintenance costs and improved reliability for vehicle owners. Furthermore, the inherent lightweight nature of silicone contributes to a decrease in overall vehicle weight, which can further enhance performance metrics such as acceleration and fuel efficiency. Overall, understanding the benefits of cac silicone hoses is essential for anyone looking to optimize their vehicle's performance and longevity.

| Dimension | Material Type | Temperature Resistance (°C) | Pressure Rating (psi) | Applications |

|---|---|---|---|---|

| 3.0" Diameter | Silicone | -60 to 180 | 30 | Intake and Intercooler |

| 4.0" Diameter | Silicone | -50 to 200 | 40 | Turbo and Supercharger |

| 2.5" Diameter | Reinforced Silicone | -40 to 150 | 35 | Cooling Systems |

| 3.5" Diameter | Silicone | -60 to 180 | 30 | Radiator Connections |

| 2.0" Diameter | Flexible Silicone | -70 to 150 | 25 | Various Applications |

When choosing the right Cac silicone hose for your vehicle, it's crucial to first evaluate your vehicle's performance requirements and goals. The automotive industry has seen a significant shift towards high-performance parts, with a report from the SEMA (Specialty Equipment Market Association) indicating that performance upgrades represent 73% of the automotive accessory market. Understanding how your vehicle is intended to perform—whether for street use, racing, or off-roading—will dictate the specifications needed in the silicone hose you select.

For instance, if you're aiming for enhanced airflow and reduced weight, silicone hoses with higher resistance to heat and pressure ratings are essential. A study published in the Journal of Automotive Engineering highlights that silicone hoses can withstand temperatures ranging from -60°C to 230°C, which is relevant for applications in high-performance engines that often operate at elevated temperatures. Furthermore, investing in reinforced silicone hoses can improve durability, particularly under the stress conditions encountered during competitive racing events, where hose failure can lead to significant performance losses or engine damage.

Ultimately, assessing your vehicle's specific performance demands—along with factors like the type of fluid the hoses will transport and their expected operating conditions—will guide you in making the right choice, ensuring that the silicone hose you select aligns perfectly with your performance goals and enhances your overall driving experience.

This chart illustrates the evaluation of different silicone hose characteristics that are critical for enhancing vehicle performance. Each criterion is rated on a scale of 0 to 100, allowing vehicle owners to assess how well a silicone hose meets their specific performance needs.

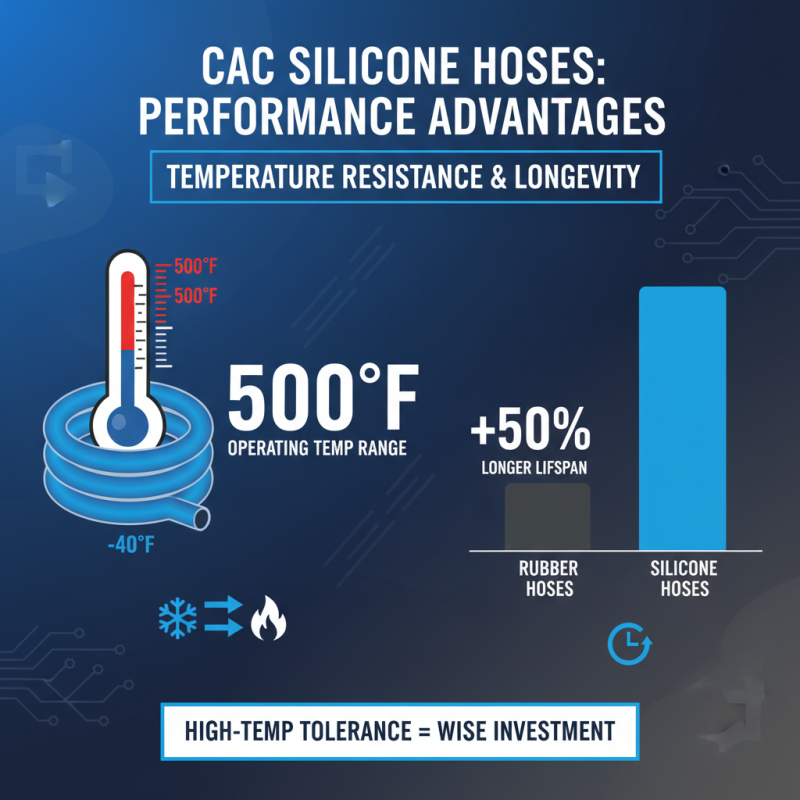

When selecting a Cac silicone hose for your vehicle’s performance needs, understanding the key factors involved can significantly enhance your decision-making process. Firstly, the temperature resistance of the silicone hose is crucial. High-quality silicone hoses typically withstand temperatures ranging from -40°F to 500°F, enabling them to maintain performance under various driving conditions. A comprehensive industry report highlights that hoses capable of enduring high temperatures often outlast their rubber counterparts by up to 50%, making them a wise investment for any performance vehicle.

Another important aspect is the design and construction of the silicone hose. Reinforcement layers within the hose can greatly affect its durability and pressure ratings. A reinforced silicone hose can handle pressures of up to 30 psi or more, a significant advantage for high-performance engines that require reliable and efficient airflow.

**Tips:** Always check the specifications for pressure ratings and temperature ranges when selecting a hose. Ensuring these match your vehicle’s requirements is key to maintaining optimal performance. Additionally, consider the diameter and length of the hose; a poorly sized hose can lead to airflow restrictions and reduce engine efficiency. Lastly, consult with automotive performance specialists when in doubt, as their insights can provide tailored solutions for your vehicle's unique requirements.

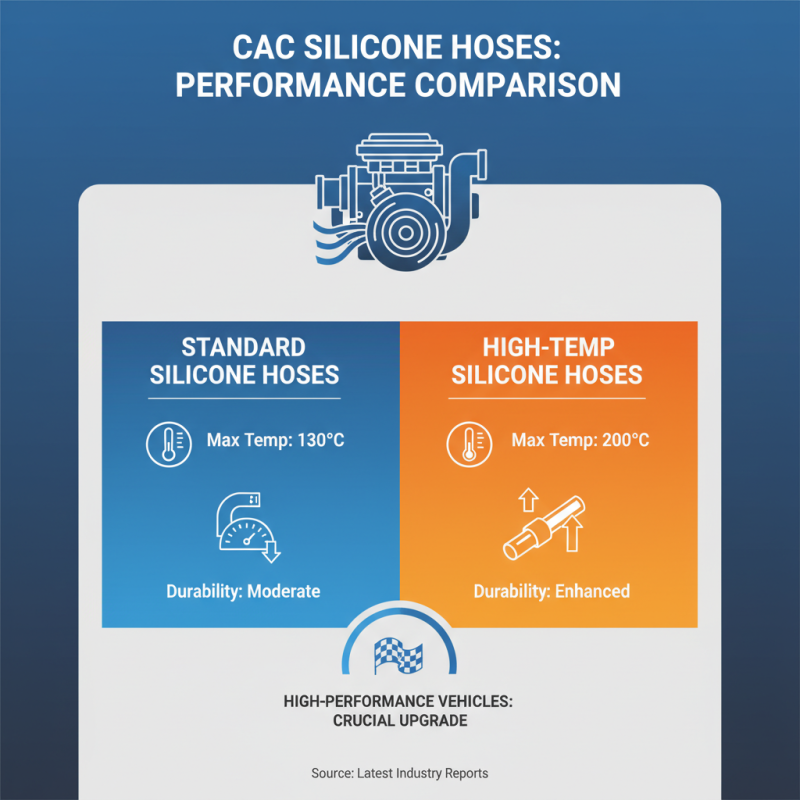

When it comes to enhancing vehicle performance, selecting the right CAC (Charge Air Cooler) silicone hose is crucial. A comparison of various types and brands reveals that silicone hoses come in different formulations and specifications, which can significantly affect their durability and performance. According to the latest industry reports, high-temperature silicone hoses can typically withstand temperatures up to 200°C, while standard options may only endure up to 130°C. This difference is vital for high-performance vehicles that operate under extreme conditions.

One major factor to consider is the construction of the hose. Multi-ply reinforced hoses provide additional strength and flexibility compared to single-ply options, making them ideal for vehicles that demand high airflow and pressure resistance. Industry data indicates that reinforced silicone hoses can offer up to 50% higher burst pressure resistance, which is essential for maintaining performance during heavy acceleration and high boosts.

Tips: When selecting a CAC silicone hose, analyze your vehicle's unique performance requirements. Measure the existing hoses to ensure a proper fit and consider your vehicle's operating temperature range. Additionally, consult technical specifications and customer reviews to assess the long-term reliability of the hoses you're considering. Ultimately, investing in high-quality silicone hoses tailored to your vehicle's needs can lead to enhanced performance and longevity.

When installing CAC silicone hoses, proper installation is crucial to ensure optimal performance and longevity. According to a report by the Society of Automotive Engineers, up to 30% of vehicle performance can be affected by improper airflow management. Therefore, ensuring that the silicone hoses are correctly fitted without any twists or kinks is essential. Always inspect the clamps to confirm they are snug and secure, as loose hose connections can lead to leaks and pressure loss, significantly diminishing engine efficiency.

Maintenance of CAC silicone hoses involves regular inspections to prevent premature wear. It’s recommended to check the hoses for signs of cracking, softness, or corrosion every few thousand miles, particularly in high-performance vehicles. A study featured in the Journal of Engineering Research states that silicone hoses have a lifespan of approximately 50,000 miles under optimal conditions, but environmental factors can reduce this. Keeping the engine compartment clean and ensuring that the hoses are free from debris can extend their life. Regularly monitoring and replacing any damaged hoses can prevent larger, more costly engine issues down the line.