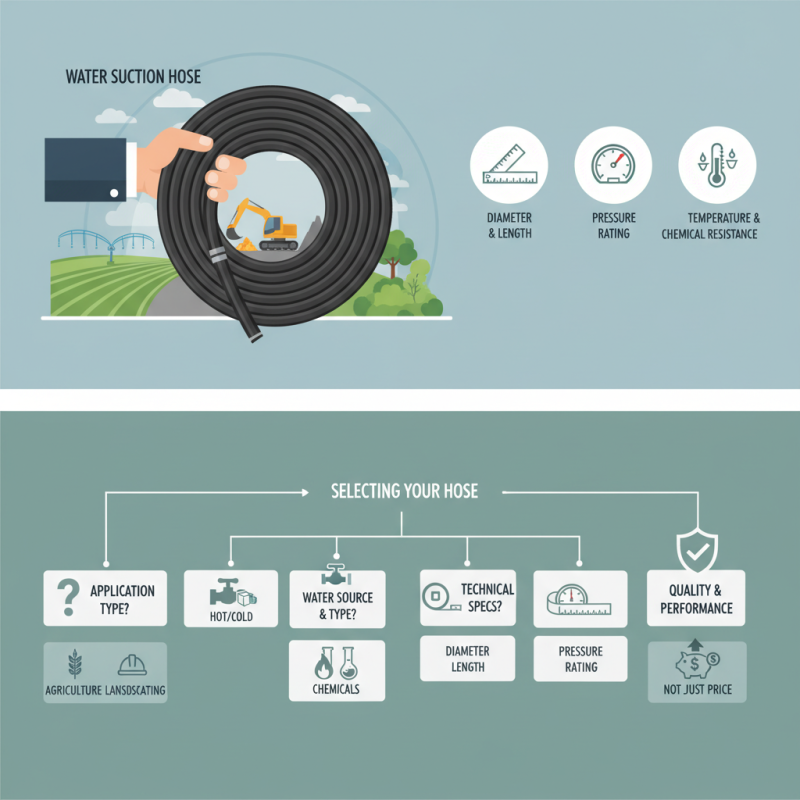

When it comes to selecting the right Water Suction Rubber Hose, many factors come into play. This essential tool is vital for transferring water in various applications. Whether you need it for agricultural use, construction, or landscaping, making the right choice is crucial.

Choosing a Water Suction Rubber Hose can feel overwhelming. With so many options available, how do you know which one suits your needs? Factors like diameter, length, and pressure ratings can influence your decision. You should also consider the environment where it will be used. For example, is it for hot or cold water? Will it be exposed to harsh chemicals?

It’s essential to reflect on your specific requirements. A hose that works perfectly for one application might be inadequate for another. Understanding your needs can save you time and money in the long run. Keep in mind, selecting the best Water Suction Rubber Hose is not just about price. Quality and performance should be equally prioritized.

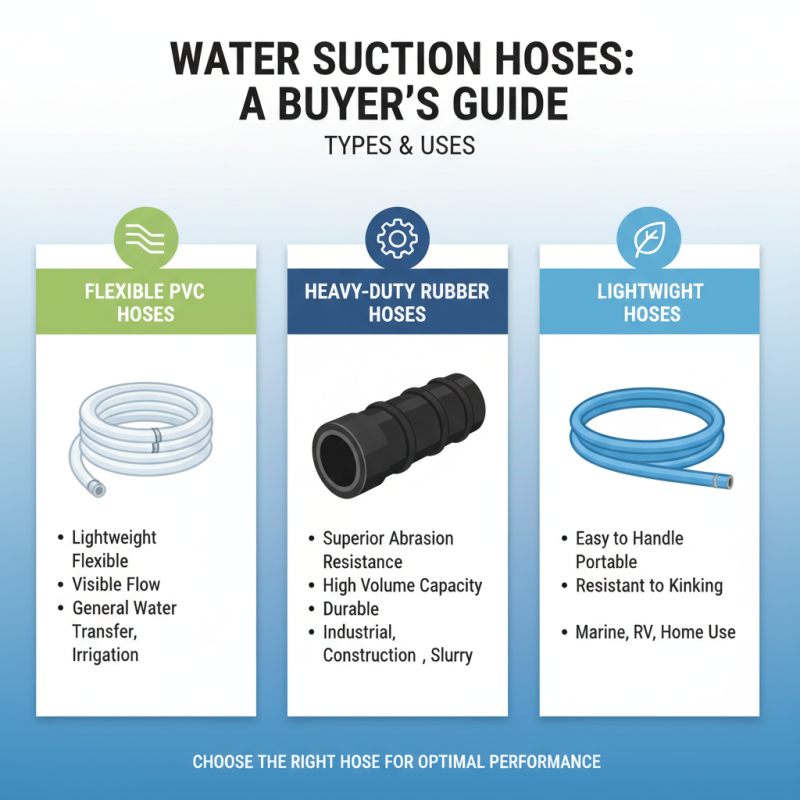

When choosing a water suction rubber hose, understanding the types available is critical. Generally, hoses differ by material composition and intended use. Common varieties include flexible PVC hoses, heavy-duty rubber hoses, and lightweight options. Each type has unique strengths suited for various applications. For instance, heavy-duty hoses offer superior abrasion resistance and can handle larger volumes of water.

Tips: Consider the temperature range. Some hoses are better for hotter conditions, while others thrive in cold environments. This factor impacts the hose's longevity and performance.

According to recent industry reports, flexible PVC hoses dominate in gardening and light construction due to their affordability and flexibility. In contrast, heavy-duty rubber hoses are preferred for industrial settings, handling pressures up to 150 psi. However, relying solely on one type may lead to unexpected downtimes.

Tips: Regularly inspect hoses for wear. Signs like cracks or discoloration can indicate a need for replacement. Understanding these signs can prevent costly failures in critical applications.

Selecting the right water suction rubber hose requires careful consideration. Key factors include material, diameter, and pressure ratings. According to industry reports, hoses made from synthetic rubber demonstrate flexibility and durability under various conditions. This is crucial for long-term use.

The diameter affects flow rate significantly. A hose that is too narrow can restrict water flow, leading to inefficient systems. The American Society of Civil Engineers suggests that proper diameter sizing can improve efficiency by up to 30%. Additionally, pressure ratings should meet the specific needs of your application. High-pressure applications require hoses that can withstand more stress. Not paying attention to these specifications could lead to unexpected failures.

Another aspect to consider is the environment in which the hose will be used. Hoses exposed to UV rays or extreme temperatures may degrade faster. It's essential to choose a product that can withstand your local conditions. Reports show that hoses often fail in harsh environments due to poor material selection. Using the wrong type can result in leaks or breaks, causing disruptions in work. Always review the specifications carefully before making a selection.

When choosing a water suction rubber hose, material durability and flexibility are key. A high-quality hose should withstand various conditions. Look for materials that resist abrasions and weathering. Rubber can offer good longevity, but not all rubber is made equal. Some might crack under extreme weather or wear out quickly.

Flexibility is equally important. A hose needs to bend easily without kinking. If it’s too stiff, it might be challenging to maneuver. Consider the environment it will be used in. A hose that's flexible in one setting may not perform well in another. Testing the hose in realistic scenarios can reveal its true performance.

Pay attention to the thickness of the hose. Thicker hoses often provide better durability but may sacrifice some flexibility. Finding the right balance can be tricky. It's essential to experiment before making a final decision. Not every option will meet expectations. Observing how a hose performs over time will lead to better choices in the future.

Choosing the right hose for water transport is crucial. Hose diameter directly impacts flow rate. A larger diameter allows more water to pass through quickly. However, a thicker hose can be bulkier and heavier. This can complicate handling and storage. Users often overlook this balance, focusing solely on capacity without considering these factors.

Length is another significant element. Longer hoses can limit water pressure due to friction loss. Every bend and twist in the hose adds to resistance. In practice, many people find themselves with hoses that are either too long or too short for their needs. Measuring accurately is essential. A mismatch can hinder efficiency and lead to frustration.

Finding the perfect hose requires trial and error. Some may choose a thicker hose for ambitious projects but regret the weight. Others may underestimate the impact of length. These choices often lead to inefficiencies. Reflecting on if the selected hose truly meets your requirements is vital. Each decision should be deliberate, ensuring it aligns with specific tasks.

| Hose Diameter (inches) | Hose Length (feet) | Max Flow Rate (GPM) | Recommended Use |

|---|---|---|---|

| 1 | 50 | 20 | Residential gardening |

| 1.5 | 75 | 30 | Light commercial use |

| 2 | 100 | 50 | Agricultural irrigation |

| 3 | 120 | 100 | Construction site pumping |

| 4 | 150 | 150 | Heavy industrial applications |

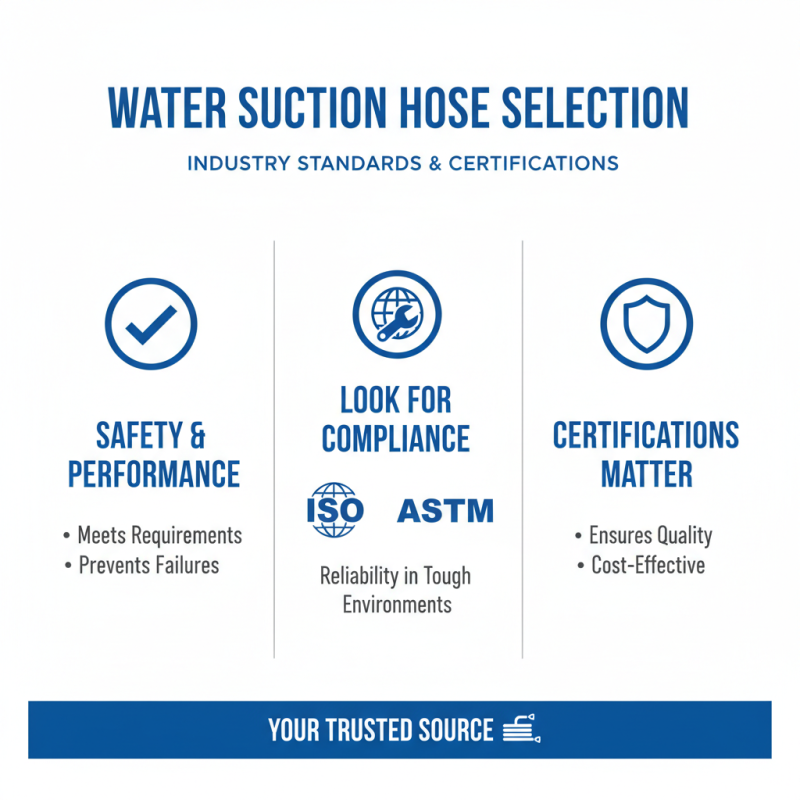

When selecting a water suction rubber hose, it’s essential to consider industry standards and certifications. These guidelines ensure that the hose meets safety and performance requirements. Look for hoses that comply with ISO and ASTM standards. Such certifications indicate reliability and can prevent costly failures in tough environments.

Quality assurance is critical, yet many overlook important details. A hose might look robust but fail under pressure. Check the burst pressure ratings listed in the specs. Inspect the material for resistance to abrasion and ozone. Hoses designed for specific applications often include tests for flexibility and temperature ranges as well.

Despite these guidelines, not all products are equal. Some might fall short of promised standards due to poor manufacturing practices. Always consult professionals before purchasing. They can provide insight into which certifications matter most for your needs. Making an informed choice can save time and reduce risks in the long run.