When selecting the right Oil Rubber Hose, expert insights can be invaluable. Johnathan Green, a prominent figure in the rubber industry, once noted, "Choosing the right hose can make or break your operations." This underscores the importance of thorough consideration.

Oil Rubber Hoses are essential in various applications, from automotive to industrial use. The wrong hose can lead to leaks or failures, posing safety risks. Each application demands specific properties, such as flexibility and resistance to oils and chemicals.

Visualize a manufacturing plant where precise oil transfer is crucial. An inappropriate hose could result in downtimes and costly repairs. Reflecting on these challenges highlights the need for proper selection. With carefully chosen components, you can boost performance and longevity.

When choosing oil rubber hoses, it’s crucial to understand their different types. Common categories include heavy-duty, lightweight, and multipurpose hoses. Heavy-duty hoses withstand higher pressures. They are designed for tough applications, such as in oil refineries or construction sites. Lightweight hoses are ideal for general use. They are easier to handle but may not endure harsh conditions.

The performance of these hoses often varies based on their material composition. According to industry reports, hoses made with synthetic rubber have better resistance to oil and other chemicals. Such hoses can last 50% longer under extreme conditions compared to standard rubber hoses. Additionally, proper temperature ranges must be considered. Most oil rubber hoses function efficiently between -20°C to 80°C. Exceeding these limits may cause premature wear or failure.

Choosing the right hose can be complex. Users must consider application specifics, including pressure, temperature, and fluid type. Mistakes in selection may lead to costly downtime or safety risks. Many professionals report that they often underestimate the importance of compatibility with fluids. This sometimes results in hose degradation. Factors like environment and exposure can influence the hose lifespan greatly.

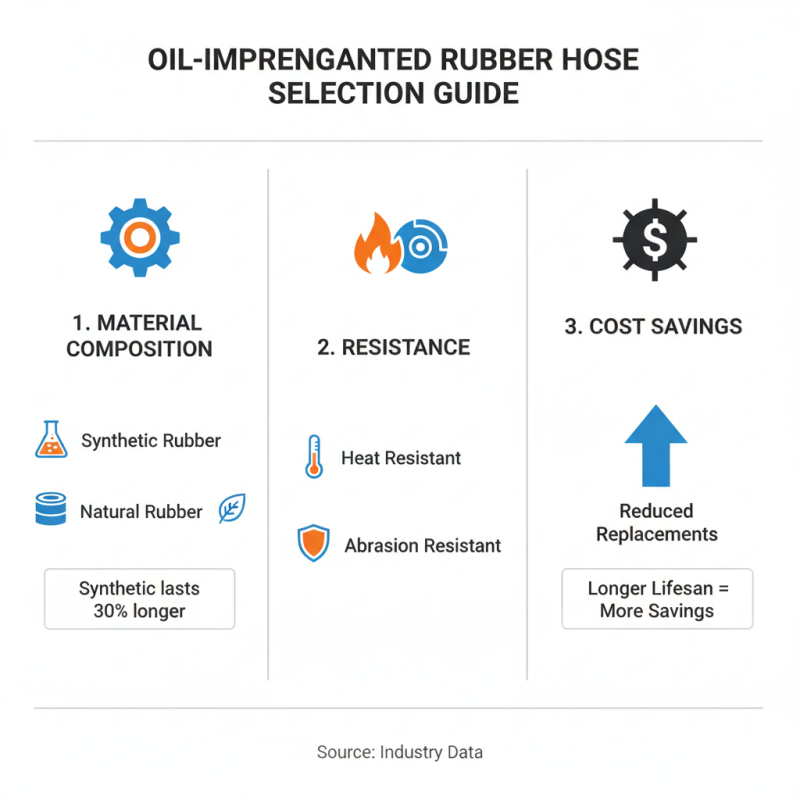

When selecting an oil rubber hose, several key factors play a critical role. Material composition is essential. High-quality rubber can resist heat and abrasion. According to industry data, hoses made of synthetic materials can last up to 30% longer than natural rubber. This can lead to significant savings in replacement costs over time.

Consider the size and pressure ratings of the hose. Make sure it matches the application requirements. Oversized hoses can lead to inefficiency. They may restrict flow and pressure, compromising performance. Ideally, look for hoses that meet or exceed your operational pressure needs.

Tips for choosing wisely: Always check for compatibility with the oil type. Not all hoses suit every oil. Some may degrade quickly. Next, assess the temperature range the hose can withstand. Harmful factors exist if you overlook this detail. A hose exposed to excessive heat risks failure. Don’t ignore the hose's flexibility. Rigid hoses can be hard to maneuver. This can complicate installation or maintenance tasks. All these aspects matter significantly in your selection.

When choosing oil rubber hoses, durability and flexibility are crucial factors. Rubber hoses must withstand varying environments. Harsh conditions can quickly deteriorate materials. A durable hose resists abrasions and pressure effectively. Look for hoses that offer protection against weather influences. For flexibility, consider the hose design and composition. A flexible hose allows for easier handling and installation.

Test different hoses in real scenarios. Bend and twist them to see how they respond. A hose that kinks easily may not meet your needs. Flexibility varies with temperature changes. Ensure the selected hose remains pliable in cold weather. It’s essential to evaluate the hose's performance under pressure. Gathering feedback from users can provide insights into long-term performance.

Lastly, take note of any visible wear and tear. Regular inspection can help identify issues early. Consider if the hose can adapt to stress and movement. Balancing flexibility with durability isn't always straightforward. Some hoses excel in one area but disappoint in another. Stay informed and adjust choices based on performance over time.

Choosing the right oil rubber hose involves understanding its compatibility with various fluids and environmental conditions. Different fluids can react differently to materials. Choose hoses that can handle the specific oils or chemicals. For example, not all rubber hoses are suitable for petroleum-based products.

When assessing compatibility, consider temperature ranges. High or low temperatures can degrade rubber over time. Ensure the hose maintains integrity in extreme conditions. Also, think about exposure to sunlight and ozone. These elements can lead to premature wear.

Here’s a quick tip: double-check the specifications. Misalignment with fluid types can result in leaks. Regular maintenance is crucial, too. Inspect hoses for any signs of wear or damage regularly. Taking time to evaluate your needs can prevent costly issues later on. Remember, it's better to be cautious than to deal with unexpected failures.

When selecting oil rubber hoses, balancing cost and quality is crucial. Many professionals face the dilemma of opting for cheaper options versus investing in higher-quality materials. A recent industry report noted that low-cost hoses often fail under pressure, leading to more frequent replacements. This can ultimately increase costs over time.

One way to make a better choice is to evaluate the hose’s material. Look for hoses that withstand high temperatures and pressures. This durability can prevent costly downtime. In fact, hoses made from synthetic rubber typically last longer than those made from cheaper materials. Consider the environment where the hose will be used. Hoses exposed to chemicals may require specialized formulations.

Another important tip is to check the certifications. Hoses compliant with industry standards ensure better reliability. According to statistics, using certified products can reduce failure rates by 30%. It’s clear that while immediate costs are significant, the long-term benefits of quality materials often outweigh them.

| Parameters | Low-Cost Options | Mid-Range Options | High-Quality Options |

|---|---|---|---|

| Material Type | Synthetic Rubber | Blend of Rubber and PVC | Premium Natural Rubber |

| Operating Temperature | -20°C to 60°C | -30°C to 70°C | -40°C to 100°C |

| Pressure Rating | 10 bar | 15 bar | 25 bar |

| Flexibility | Basic Flexibility | Good Flexibility | Excellent Flexibility |

| Durability | 1-2 Years | 3-5 Years | 5-10 Years |

| Typical Applications | Light Industrial | Commercial Use | Heavy-Duty Industrial |