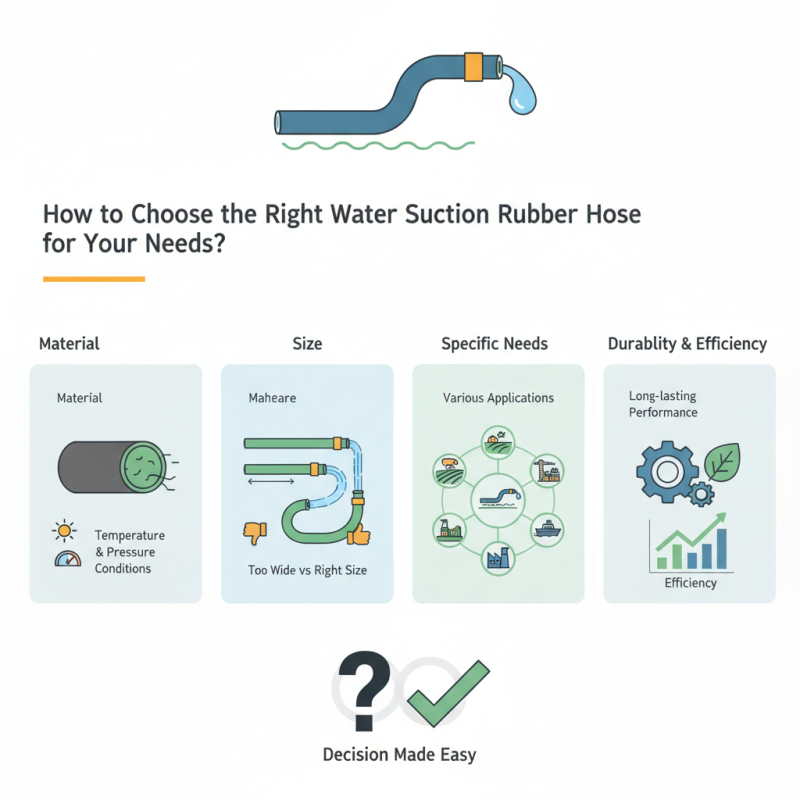

Choosing the right Water Suction Rubber Hose is crucial for various applications. A suitable hose ensures efficiency and durability. This task may seem simple, but several factors influence your decision.

Consider the material of the hose. Rubber offers flexibility and strength, but not all rubber hoses are created equal. Different environments require different grades. Think about the temperature and pressure conditions. These can affect performance significantly.

Additionally, the size of the hose matters. Too wide or too narrow can lead to problems. It’s also important to reflect on your specific needs. Not every hose will fit every application. This decision is not just about function; it reflects your understanding of the job at hand.

When selecting a water suction rubber hose, several factors are important. The hose must endure varying pressure levels. Most industrial hoses handle pressures between 20 to 100 PSI. Understanding the specific pressure needs of your application is crucial. A mismatch can lead to hose failure.

Material choice is another key factor. Rubber hoses come with different compounds, affecting durability and flexibility. High-grade rubber can withstand harsher conditions and temperature variations. For outdoor use, consider UV resistance to prolong the hose's lifespan. A report from the Rubber Manufacturers Association indicates that 30% of hose failures stem from poor material selection.

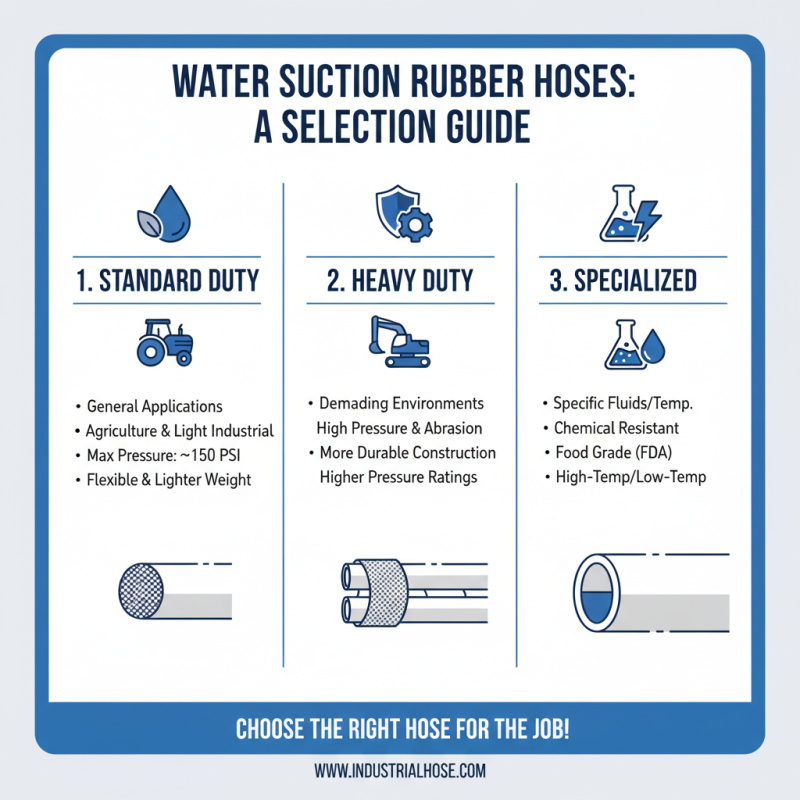

When selecting the right water suction rubber hose, understanding the different types available is essential. There are generally three main types: standard, heavy-duty, and specialized hoses. Standard hoses are suitable for general applications and are often used in agriculture and light industrial tasks. They can handle pressures up to 150 PSI, depending on the size. Heavy-duty hoses, on the other hand, are more durable. They can withstand higher pressures and are better suited for challenging environments.

Specialized hoses come with added features, such as abrasion resistance or chemical compatibility. Data shows that users often overlook the importance of hose thickness and materials. A thicker wall generally provides better durability and resistance to wear. Rubber compositions can vary significantly among manufacturers. Many surveys indicate that 40% of hose failures are attributed to improper selection based on application needs.

In practice, environmental factors must also be considered. Temperature changes, UV exposure, and chemical exposure can affect hose performance. Users frequently underestimate these factors, leading to premature hose failure. Calling for more thorough research and evaluation of options could save both time and money. Selecting the wrong hose type can result in leaks, inefficiencies, and safety hazards.

When choosing a water suction rubber hose, the diameter and length are crucial. The diameter affects the flow rate. A larger diameter allows more water to pass through quickly. However, a hose that is too large may be heavy and difficult to manage. Smaller diameters may restrict flow but are easier to handle. It's vital to visualize your need. A garden requires less water flow compared to a construction site.

Length is equally important. A longer hose increases flexibility but can lead to pressure loss. Careful measurements are necessary. Imagine needing to cover a distance of 50 feet. A longer hose than needed might tangle and complicate the task. On the other hand, a short hose limits your reach and may cause inconvenience. Reflect on your regular tasks. Assess if you often have tight spaces or large areas to cover.

Consider your environment. A hose used in rugged conditions may require added durability. Different settings demand different specifications. It is good to be cautious here. Mistakes can lead to frustration and wasted resources. Take time to evaluate your needs. Focus on practical aspects. Each choice impacts your experience with the hose.

When choosing a water suction rubber hose, consider material durability first. Different hoses use various materials that affect their lifespan. For instance, a thick rubber hose may resist abrasion better than a thinner one. Flexible hoses are essential for applications involving tight bends. A good quality hose will bend easily without cracking.

**Tip:** Always check the temperature range of the hose material. Extreme heat or cold can affect performance. If left untested, it may lead to unexpected failures.

Flexibility is another critical factor. A hose that is too rigid can break under stress. On the other hand, overly flexible hoses may not withstand harsh conditions. For agricultural applications, a medium flexibility hose usually wins. It strikes a balance between strength and ease of use.

**Tip:** Test the hose before full deployment. A small patch can reveal weaknesses. Sometimes, the most durable-looking hoses are not as sturdy as they appear. Adjust your choice based on actual performance rather than just specifications.

This chart evaluates the durability and flexibility of different materials used in water suction rubber hoses, highlighting their performance across various applications.

Selecting the right water suction hose involves understanding the temperature range it can handle. Water suction hoses are regularly used in construction, agriculture, and drainage applications. Each application may require different temperature tolerances.

The operating temperature for water suction hoses typically ranges from -40°F to 158°F (-40°C to 70°C). According to industry data, the material composition of the hose plays a crucial role in its temperature tolerance. For example, rubber hoses tend to perform better in varying temperatures compared to PVC counterparts. The right choice depends on the specific use case.

Misjudging temperature needs can lead to premature failure of the hose. Rubber hoses endure hot water transport better. However, excessive heat can degrade rubber over time. On the flip side, in cold weather, hoses may become rigid and crack. Recognizing these limits can prevent costly mistakes and ensure reliable performance in critical operations.