When it comes to efficiently transporting water for various applications, selecting the appropriate Water Suction Rubber Hose is crucial. This type of hose is specially designed to handle the demands of suction and discharge in a wide range of environments, from construction sites to agricultural fields. Understanding the specific requirements of your project and the characteristics of different hoses will enable you to make a well-informed decision that ensures optimum performance and longevity.

Choosing the right Water Suction Rubber Hose involves considering factors such as the hose's diameter, length, flexibility, and resistance to environmental factors. It is essential to match these specifications to the intended application, whether it be irrigation, drainage, or industrial use. Moreover, understanding the material composition and the operating conditions will play a vital role in ensuring that the hose can withstand pressures and physical stresses without failure.

In summary, making an informed choice about a Water Suction Rubber Hose can significantly impact the efficiency and reliability of your water transportation tasks. By carefully evaluating your needs and the hose specifications, you can ensure that your selection will meet the performance standards required for your specific application, thereby leading to successful project outcomes.

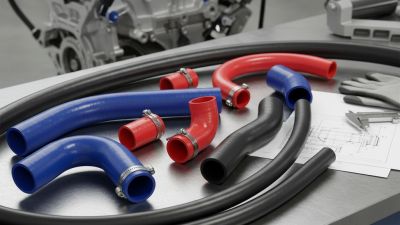

Water suction rubber hoses are essential components used in various industries for transporting water and other fluids. The primary types of water suction hoses include lightweight PVC hoses, reinforced rubber hoses, and heavy-duty options designed for industrial applications. Each type serves a specific purpose, influenced by factors such as flexibility, durability, and pressure resistance. For instance, lightweight PVC hoses are suitable for agricultural applications and small-scale water transfer, while heavy-duty rubber hoses are preferred in construction and mining, where more robust performance is required.

Applications of water suction rubber hoses are vast and varied. In agriculture, they are used for irrigation and drainage systems, allowing efficient water transfer from one location to another. In the construction sector, these hoses play a crucial role in dewatering projects, handling high volumes of water to maintain dry work sites. According to the Rubber Manufacturers Association, the global market for rubber hoses is projected to grow at a CAGR of 3.5% from 2021 to 2026, driven by the increasing demand in construction and agricultural practices. Understanding the specific requirements of your application—such as temperature, pressure ratings, and medium compatibility—will help ensure you select the right water suction rubber hose for optimal performance and longevity.

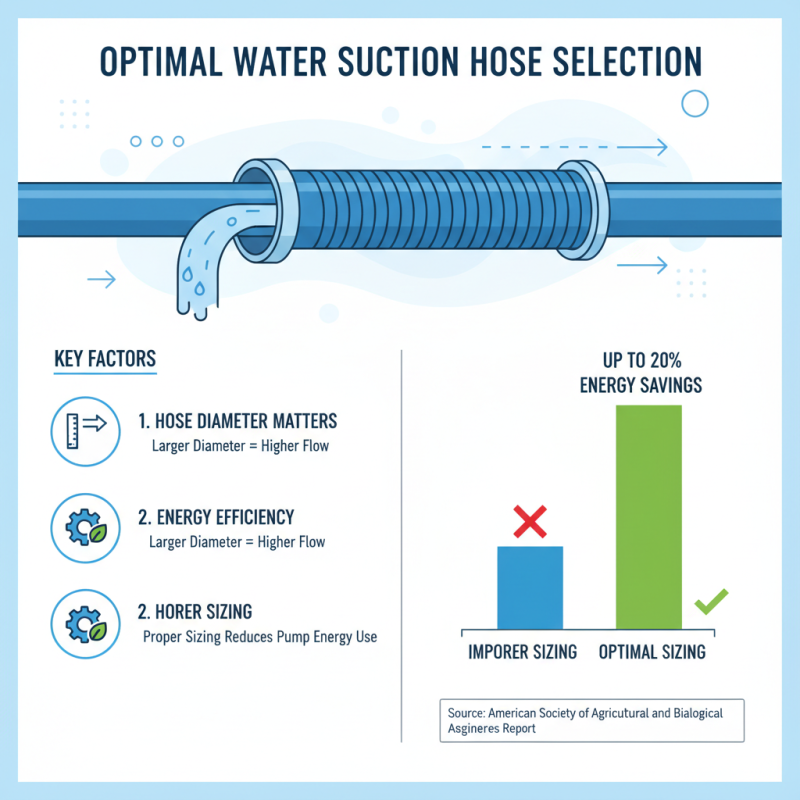

When selecting the right water suction rubber hose, several key factors should be closely evaluated to ensure optimal performance for your specific application. First and foremost, the hose's diameter is critical; a larger diameter can facilitate higher flow rates, which is essential for demanding tasks such as agricultural irrigation or construction site dewatering. According to a report by the American Society of Agricultural and Biological Engineers, proper hose sizing can reduce pump energy consumption by up to 20%, emphasizing the importance of making informed decisions around hose specifications.

Another important consideration is the working pressure and temperature tolerance of the hose. Water suction hoses are typically rated for a certain level of pressure, and understanding the requirements of your project is crucial to prevent hose failure. For instance, a study from the Rubber Manufacturers Association indicates that hoses should be able to withstand at least 1.5 times the intended working pressure to ensure safety and reliability. Additionally, evaluating the rubber composition and reinforcement material can provide insights into the hose’s flexibility, durability, and resistance to environmental factors such as UV exposure and abrasion, which can significantly extend the product's lifespan in rugged conditions.

Lastly, consider the environment in which the hose will be used. Factors such as exposure to chemicals, varying temperature extremes, and physical abrasion from surrounding elements can vastly affect the performance and longevity of the water suction hose. A thorough assessment of these conditions, backed by material compatibility charts and pressure duration insights from industry reports, can lead to a more effective and reliable selection that meets the demands of both commercial and residential applications.

When selecting a water suction hose, material selection is crucial as it affects the hose's performance, durability, and suitability for specific applications. Rubber hoses are often preferred due to their inherent flexibility, resistance to various temperatures, and ability to withstand high pressure. Rubber is also less prone to cracking compared to other materials, making it a reliable choice for environments that may expose the hose to rough usage or extreme conditions. Additionally, rubber hoses can offer excellent chemical resistance, which is beneficial in applications involving various liquids.

On the other hand, alternatives such as PVC or polyurethane hoses may be more lightweight and cost-effective, making them appealing for occasional use or less demanding environments. While these options can be adequate for light-duty tasks, they may not outperform rubber hoses in durability and resilience, especially in heavy-duty applications. Moreover, their flexibility and resistance to certain chemicals may also be limited, constraining their usability in diverse scenarios. Therefore, understanding the trade-offs between rubber and other materials is essential to ensure that the chosen hose meets the specific needs of the task at hand.

| Hose Type | Material | Temperature Range (°C) | Pressure Rating (psi) | Flexibility | Durability |

|---|---|---|---|---|---|

| Rubber Suction Hose | Nitrile Rubber | -30 to 70 | 150 | High | Excellent |

| PVC Suction Hose | PVC | 0 to 60 | 80 | Medium | Good |

| Reinforced Hose | Rubber with Polyester Reinforcement | -20 to 80 | 200 | High | Very Good |

| Silicone Hose | Silicone | -40 to 180 | 50 | Very High | Excellent |

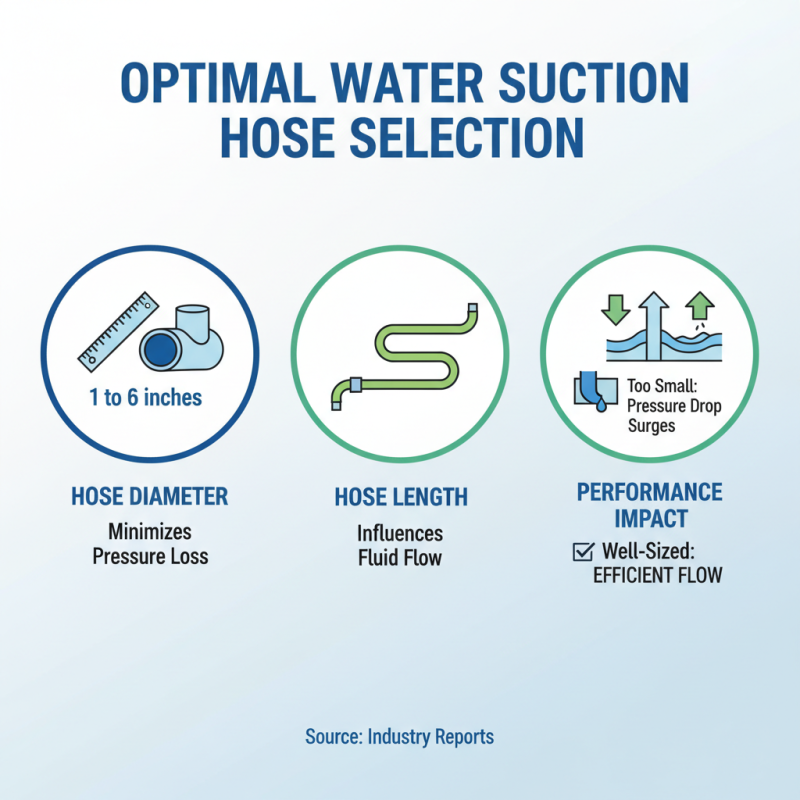

When selecting a water suction rubber hose, sizing and length are critical factors that influence performance and efficiency. According to industry reports, a well-sized hose can minimize pressure loss, ensuring optimal fluid flow. For instance, a hose that is too large may lead to surges in fluid dynamics, while a hose that is too small can create significant pressure drops that hinder performance. A proper diameter typically falls within 1 to 6 inches for most applications, depending on the volume of water being moved, as well as the type of suction system involved.

Length is also an essential consideration. Research indicates that every foot of hose length can contribute to additional friction loss; for example, a longer hose can decrease the system's overall efficiency. The American Society of Plumbing Engineers (ASPE) suggests calculating the friction loss per 100 feet of hose to determine the ideal length to maintain the required flow rate. Targeting the shortest feasible length for a given application, while accounting for bends and fittings, is advised as it optimizes both performance and durability. Employing these sizing and length strategies can result in more effective water evacuation, enhancing overall operational efficiency in various settings.

Maintaining your water suction rubber hose is crucial to ensure its longevity and optimal performance. Regular inspection for wear and tear is essential; check for cracks, leaks, and signs of deterioration. If you notice any issues, replacing the hose promptly can prevent further damage and ensure efficient operation. Always store the hose in a cool, dry place when not in use to protect it from UV rays and extreme temperatures.

Here are some tips for prolonging the lifespan of your water suction rubber hose. First, avoid kinking or twisting the hose during use, as this can lead to internal damage. Use proper fittings that match the hose size and type to prevent stress and strain. Additionally, consider using a hose reel for storage, which helps maintain its shape and prevents tangling. Lastly, rinse the hose after each use to remove any debris or contaminants that may cause internal damage over time.

By following these maintenance tips and being attentive to your hose's condition, you can extend its useful life and ensure it operates effectively when you need it most.