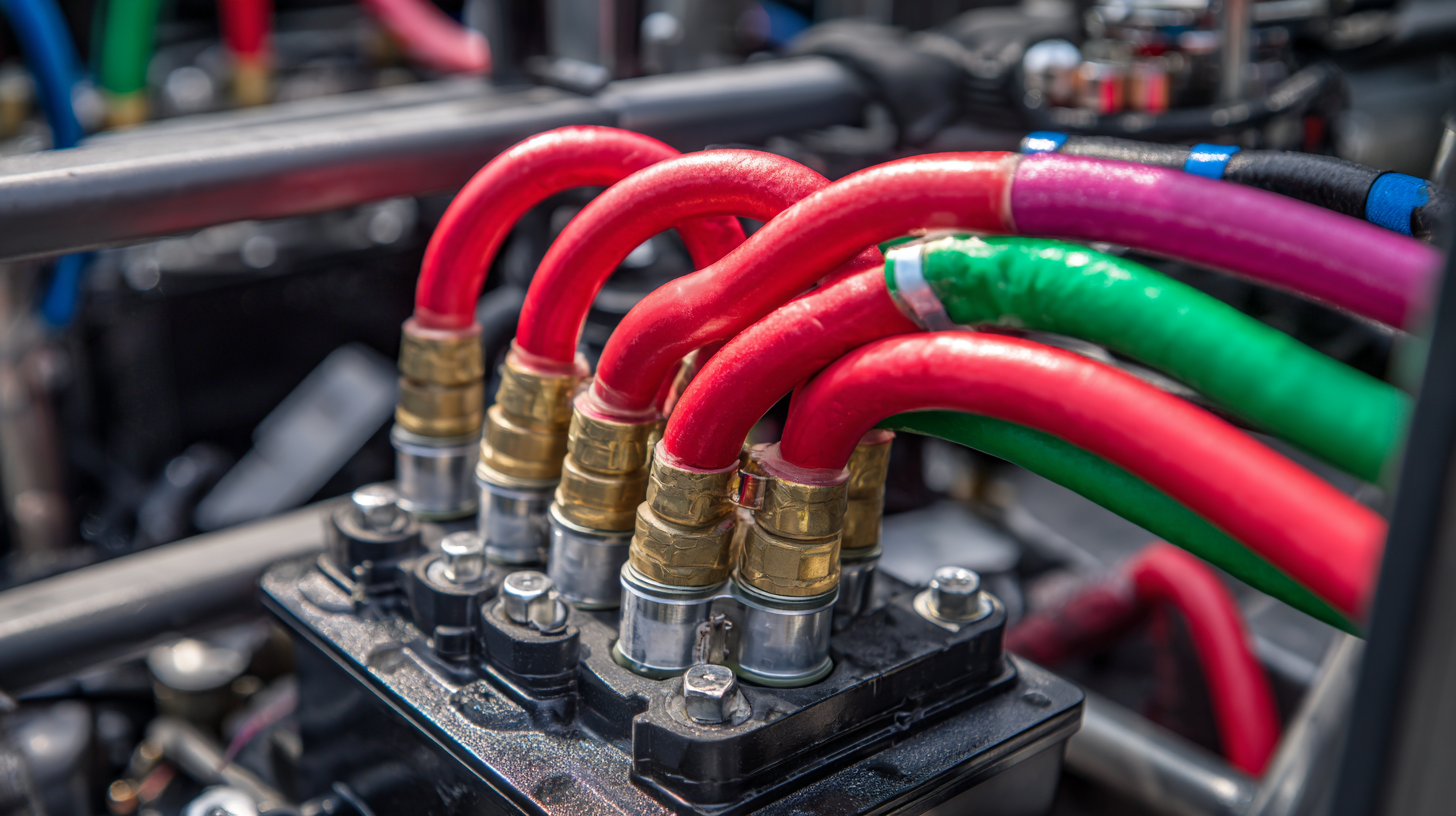

When it comes to selecting the ideal Fuel Cells Silicone Hose for your application, the decision can significantly affect performance and efficiency. Fuel Cells Silicone Hoses are engineered to withstand high temperatures and pressures, making them essential components in various automotive and industrial settings. Choosing the right type hinges on understanding your specific needs, including the operating environment, chemical compatibility, and pressure requirements. This article delves into the various types of Fuel Cells Silicone Hoses available, their unique characteristics, and crucial considerations to ensure you make an informed choice. Understanding these factors will not only enhance the efficiency of your fuel cell systems but also prolong their lifespan, ultimately contributing to more sustainable and performance-driven solutions.

When selecting a silicone hose for fuel cells, several key factors must be considered to ensure optimal performance. First and foremost, the temperature and pressure requirements of your specific application are critical. Silicone hoses come in various grades, designed to withstand high temperatures and pressures, making them suitable for different fuel cell environments. It's essential to match the hose material to the operating conditions to prevent degradation or failure, which could compromise the system's efficiency.

Another important consideration is the hose diameter and length. The dimensions directly affect the flow rate and pressure drop within the fuel cell system. Choosing the right diameter will help maintain the proper flow, while the hose length should be minimized to reduce potential restrictions. Additionally, pay attention to the connections and fittings, as improper sealing can lead to leaks and system inefficiencies. By carefully evaluating these factors, you can select a silicone hose that meets the unique demands of your fuel cell application and enhances overall performance.

| Factor | Description | Importance Level | Recommended Action |

|---|---|---|---|

| Temperature Resistance | Ability to withstand temperature fluctuations without degrading. | High | Select hoses rated for your specific temperature range. |

| Chemical Compatibility | Resistance to degradation from fuels and other chemicals. | High | Verify compatibility with the specific fuels used. |

| Pressure Rating | Maximum internal pressure the hose can handle safely. | Medium | Choose hoses that exceed your application’s pressure requirements. |

| Hose Diameter | Internal diameter affects flow rate and pressure drop. | Medium | Calculate required diameter based on application needs. |

| Length | Total length of the hose impacting installation and flexibility. | Low | Measure accurately for optimal fitting and performance. |

| Flexibility | Ease of routing in tight spaces without kinking. | Medium | Choose hoses designed for high flexibility when needed. |

When selecting the right silicone hose for fuel cell applications, understanding the chemical compatibility of these hoses is essential. Silicone hoses are widely used in fuel cell systems due to their

excellent thermal stability and flexibility. However, their performance can be significantly affected by the types of fuels and chemicals they come into contact with, making compatibility assessments crucial.

For instance, a recent study indicated that certain silicone compounds may degrade when exposed to specific fuels or operating conditions, which could lead to reduced efficiency or unexpected failures in the fuel cell system.

In the context of advancements in fuel cell technology, collaborations, such as that seen in the recent partnership for marine fuel cell hoses, highlight the importance of using high-quality materials that can withstand rigorous environments.

Industry reports suggest that the global fuel cell market is expected to grow at a CAGR of over 20% in the next five years, driven by the increasing demand for clean energy solutions. To support this growth, companies must not only focus on fuel cell efficiency but also on the reliability of the components used, especially silicone hoses, which must be capable of handling varying chemical environments while maintaining performance integrity.

When selecting a silicone hose for fuel cell applications, temperature resistance is a crucial factor that cannot be overlooked. Fuel cell systems operate in a range of temperature conditions, often exceeding 80°C (176°F) during operation. According to a report from the Fuel Cell Technologies Office, materials used in fuel cells must withstand these high temperatures while maintaining performance integrity and preventing degradation. Silicone hoses are particularly favored for their ability to endure these extremes, with high-quality silicone materials demonstrating temperature resistance up to 200°C (392°F) or more.

Moreover, the effectiveness of silicone hoses in fuel cell applications is not solely dependent on temperature resistance; compatibility with various fluids circulating within the system also plays an essential role. Data from industry analysis indicates that silicone hoses exhibit superior resistance to fuel cell fluids and steam, which can be damaging to standard materials. When you evaluate potential hoses, examining their temperature ratings in conjunction with their chemical compatibility and longevity under thermal stress can lead to informed decisions that enhance the overall performance of your fuel cell system.

When selecting the right fuel cells silicone hose for your application, understanding the importance of diameter and length is crucial. The diameter of the hose directly influences the flow rate of the fuel, which is vital for maintaining optimal performance in sensitive fuel cell systems. Choosing a hose with an appropriate internal diameter ensures that the fuel can flow freely without causing pressure drops that could hinder efficiency or lead to system failures. A diameter that is too small can restrict flow, while one that is too large may lead to excessive weight and cost, making precision in this aspect essential.

Length is another critical factor that cannot be overlooked. The longer the hose, the greater the potential for pressure loss along its length due to friction. Therefore, it’s important to assess the specific requirements of your installation environment. Keeping the hose as short as possible while still accommodating your design needs not only helps maintain fuel pressure but also minimizes weight and complexity in routing. Careful consideration of both diameter and length will ensure that your fuel cells silicone hose supports the reliable and efficient operation of your fuel cell application.

When selecting silicone hoses for fuel cell applications, understanding the delicate balance between cost and performance is crucial. High-quality silicone hoses may come with a higher upfront cost, but their durability and efficiency can lead to significant long-term savings. Investing in premium hoses can result in better fuel flow, reduced maintenance costs, and enhanced safety by withstanding extreme temperatures and pressures.

**Tips:** Always consider the specific requirements of your fuel application. Look for hoses that meet industry standards and possess certifications, ensuring they are suitable for the chemicals and temperatures involved in your operation. Also, evaluate the reputation of the manufacturers; reliable brands typically offer products that deliver superior performance and longevity.

Keep in mind the importance of lifecycle cost when budgeting. Sometimes, a lower initial investment can lead to frequent replacements and downtime, outweighing the benefits. Analyze the total cost of ownership, factoring in maintenance, durability, and performance efficiency, to make an informed decision that aligns with your application's needs.