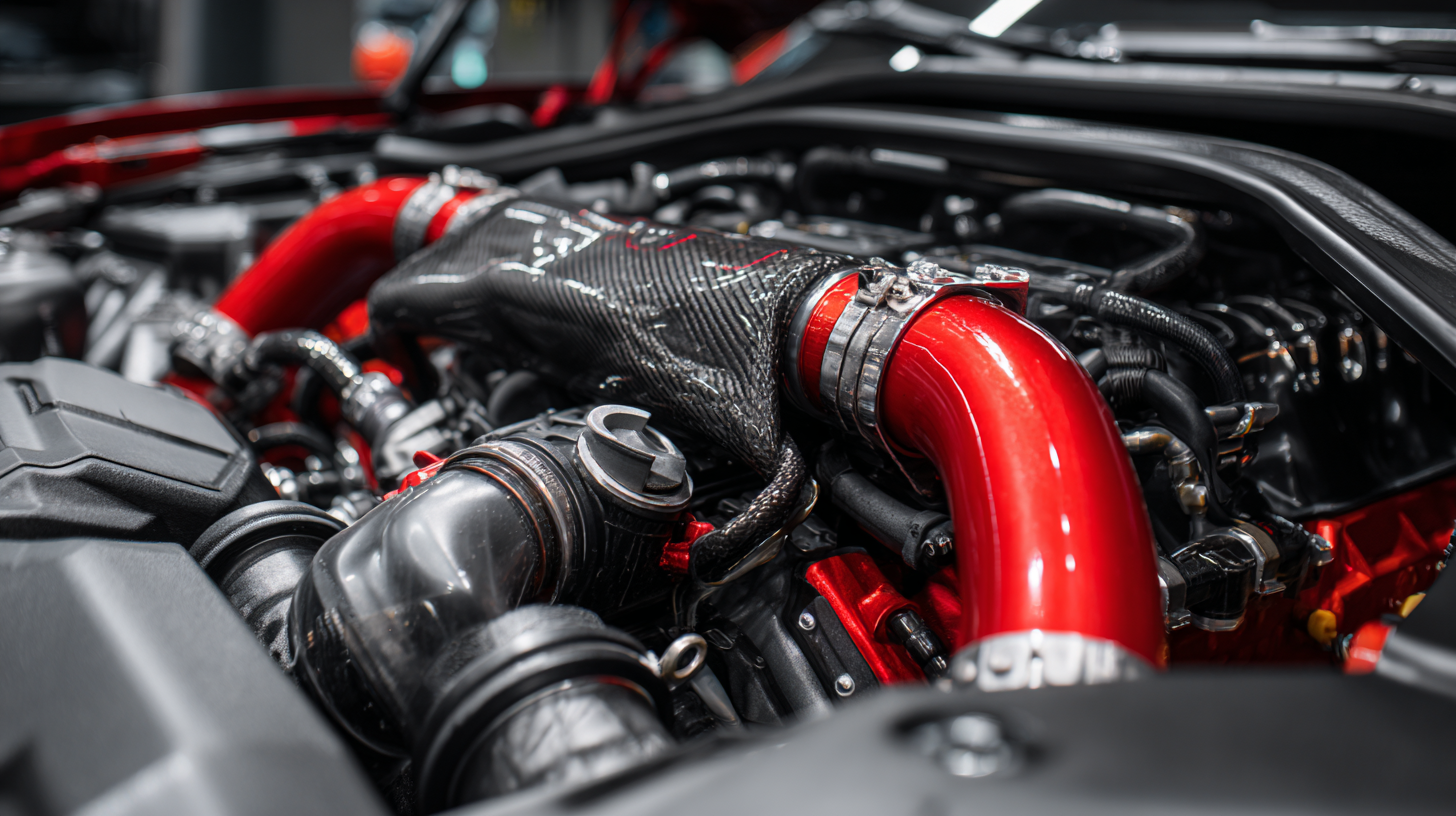

In the world of automotive performance, the choice of components can significantly impact engine efficiency and power output. Among these components, the Silicone Intake Hose has emerged as a preferred choice for many car enthusiasts and professionals alike. Research indicates that using silicone hoses can enhance airflow by up to 20% compared to conventional rubber hoses, translating to improved throttle response and engine performance. Moreover, silicone intake hoses are known for their durability and heat resistance, often operating effectively in temperatures exceeding 200°C. As the industry increasingly prioritizes performance and reliability, selecting the right Silicone Intake Hose becomes crucial for optimizing engine functionality.

This guide will explore various alternatives to silicone hoses, their benefits, and how to make an informed choice that best meets your engine's needs.

When selecting a silicone intake hose for your engine, there are several key factors to consider to ensure optimal performance and reliability. First and foremost, the diameter of the hose must match your engine's specifications. An incorrect diameter can lead to airflow restrictions or leaks, affecting engine performance. Always measure the existing hoses or refer to your vehicle's manual for the correct size.

Another essential aspect is the temperature resistance of the silicone material. High-performance engines can generate significant heat, and using a hose that can withstand these temperatures is crucial. Look for hoses labeled with high-temperature ratings, typically above 200°C (392°F), to ensure they can handle the demanding environment.

Lastly, consider the flexibility and durability of the hose. A flexible hose can easily fit into tight spaces, while a durable construction will resist wear and tear over time. Ensure the hose you select is reinforced for added strength, as this can prevent kinking and bursting under pressure.

Investing time in choosing the right silicone intake hose will pay off in the long run by enhancing engine efficiency and longevity.

When selecting a silicone intake hose for your engine, understanding the

three common types is crucial to making an informed decision. The most prevalent options include

straight hoses,

elbow hoses, and

reducer hoses. Each type serves unique purposes and boasts particular benefits.

For instance, straight hoses are favored for their direct airflow, which minimizes turbulence and enhances performance. In contrast, elbow hoses can navigate

tight spaces in engine compartments, making them essential for custom setups. Lastly, reducer hoses facilitate transitions between different-sized fittings,

ensuring a secure fit and optimal flow.

When selecting a silicone intake hose for your engine, understanding the

three common types is crucial to making an informed decision. The most prevalent options include

straight hoses,

elbow hoses, and

reducer hoses. Each type serves unique purposes and boasts particular benefits.

For instance, straight hoses are favored for their direct airflow, which minimizes turbulence and enhances performance. In contrast, elbow hoses can navigate

tight spaces in engine compartments, making them essential for custom setups. Lastly, reducer hoses facilitate transitions between different-sized fittings,

ensuring a secure fit and optimal flow.

Tip: When installing silicone intake hoses, always ensure proper clamps are used.

Over-tightening can lead to hose damage, while under-tightening can create leaks, negatively impacting engine performance.

A 2021 automotive evaluation report indicated that using high-quality silicone intake hoses can improve airflow efficiency by up to

15%. This efficiency isn’t just about power; it can also enhance fuel economy. Investing

in the right type can yield significant long-term benefits for any performance vehicle enthusiast.

Tip: Consider the temperature rating and durability of the silicone. High-grade

silicone hoses can withstand extreme temperatures and resist wear, ensuring longevity and consistent performance in challenging environments.

When it comes to maintaining optimal engine performance, recognizing the signs that indicate it's time to upgrade your silicone intake hose is crucial. Here are seven key indicators that suggest you need to make this upgrade. First, if you notice any cracks or visible wear on your current hose, this is a clear sign it's time for a replacement. A damaged intake hose can lead to reduced air flow and decreased engine efficiency.

Additionally, if your engine experiences irregular idling or stalling, it may signal an issue with the intake system. These symptoms can arise from air leaks, which compromises the air-fuel mixture and impacts performance. Regular checks for any signs of deterioration or wear, especially for hoses exposed to high temperatures, can help prevent these issues.

Tips: Always choose a silicone intake hose designed to withstand high temperatures and pressures to ensure durability. When upgrading, consider the diameter of your intake hose; a wider hose can improve air flow significantly. Lastly, don't forget to check for any loose connections and secure them properly to maintain an effective seal. Keeping these aspects in mind will help you make an informed choice for your engine's needs.

When it comes to enhancing engine performance, choosing the right silicone intake hose is crucial. High-quality silicone hoses are designed to withstand extreme temperatures and pressures, making them a preferred choice among automotive enthusiasts. According to a recent report by the Specialty Equipment Market Association (SEMA), silicone intake hoses can improve airflow by up to 15% compared to standard rubber hoses, leading to enhanced engine efficiency and horsepower.

Several top brands in the market are renowned for their high-quality silicone intake hoses. Brands like Mishimoto and HPS Performance are often highlighted for their durability and performance-focused designs. Mishimoto, for instance, offers hoses that are tested to endure temperatures exceeding 300°C, as noted in their product specifications. Meanwhile, HPS Performance combines premium silicone with reinforced layers to provide superior pressure resistance, which is essential for optimal engine performance. Investing in these brands ensures that you're not only upgrading your vehicle's aesthetic but also its overall functionality.

When installing silicone intake hoses, proper technique and attention to detail are crucial for optimal performance. First, ensure that all surfaces are clean and free of debris before installation. This prevents any obstructions that could hinder airflow. Next, use a lubricant designed for silicone to help the hose slide into place more easily. This step is especially important for tighter fittings to avoid damaging the hose during installation.

After securing the hose, it’s essential to regularly inspect the clamps and connections. Over time, vibrations from the engine can loosen fittings, leading to potential leaks. If you notice any signs of wear, such as cracks or discoloration in the silicone, replace the hose promptly to maintain efficiency. Finally, remember to avoid using overly aggressive chemicals or cleaners on the silicone, as they can degrade the material. With these tips, you can ensure your silicone intake hoses perform reliably for your engine's demands.

| Dimension | Material Type | Temperature Resistance (°C) | Pressure Rating (psi) | Typical Applications |

|---|---|---|---|---|

| 3 inches | Silicone | 200 | 30 | Turbocharged engines |

| 4 inches | Reinforced Silicone | 220 | 40 | Performance Racing |

| 2.5 inches | High-Temperature Silicone | 250 | 25 | General Automotive |

| 3.5 inches | Silicone Blend | 180 | 35 | Custom Applications |

| 5 inches | Heavy-Duty Silicone | 300 | 50 | Heavy Machinery |