Fluorosilicone Hose is gaining attention in various industries. Its unique properties make it a preferred choice for applications requiring high resistance to chemicals and extreme temperatures. According to a recent market report, the demand for fluorosilicone products is projected to grow steadily, with a compound annual growth rate of about 5.2% over the next five years. This growth highlights the need for reliable and durable hoses in aerospace, automotive, and industrial applications.

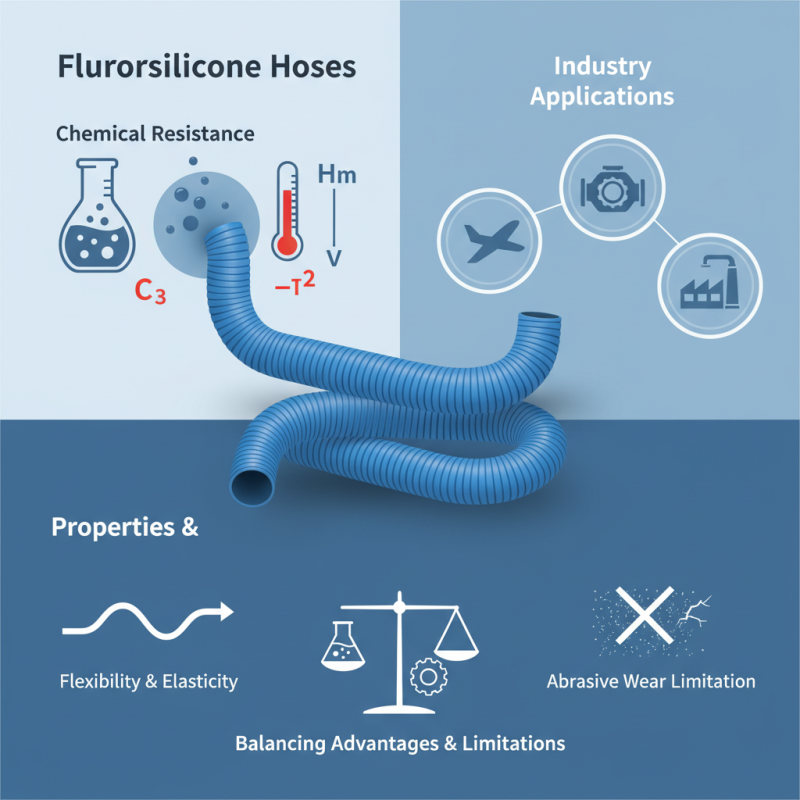

Fluorosilicone Hose offers impressive flexibility and elasticity. Yet, some users may overlook potential limitations. For example, while these hoses excel in certain environments, they can be susceptible to wear in abrasive settings. A careful evaluation of application requirements is essential to ensure optimal performance. In sectors where reliability is crucial, the characteristics of fluorosilicone can be both a boon and a challenge.

As industries increasingly rely on Fluorosilicone Hose, understanding its applications becomes vital. Users must balance the advantages of high chemical resistance with any limitations. This knowledge will drive innovation and improvement in hose technology and help manufacturers meet the evolving demands of their clients.

Fluorosilicone hoses are specialized components made from fluoroelastomer and silicone rubber. Their unique composition allows them to withstand extreme temperatures and resist chemicals effectively. This makes them suitable for demanding applications such as aerospace and automotive industries. According to a report by MarketsandMarkets, the global market for fluorosilicone materials is projected to reach $650 million by 2026, reflecting the growing need for high-performance materials.

The structure of these hoses includes a combination of silicone's flexibility and fluoroelastomer's durability. This blend enhances their resistance to fuels, oils, and solvents. Various industries utilize them to manage high-pressure systems. Some experts note that while fluorosilicone hoses excel in harsh environments, they can be more expensive compared to standard hoses. This cost factor often leads to critical considerations during selection processes.

Manufacturers often face challenges regarding the consistent quality of these hoses. Variations in production methods may lead to inconsistent performance. Proper testing is essential to ensure reliability in applications. Furthermore, while their performance is commendable, not every application benefits from fluorosilicone hoses. Companies must assess their specific needs before committing to such materials.

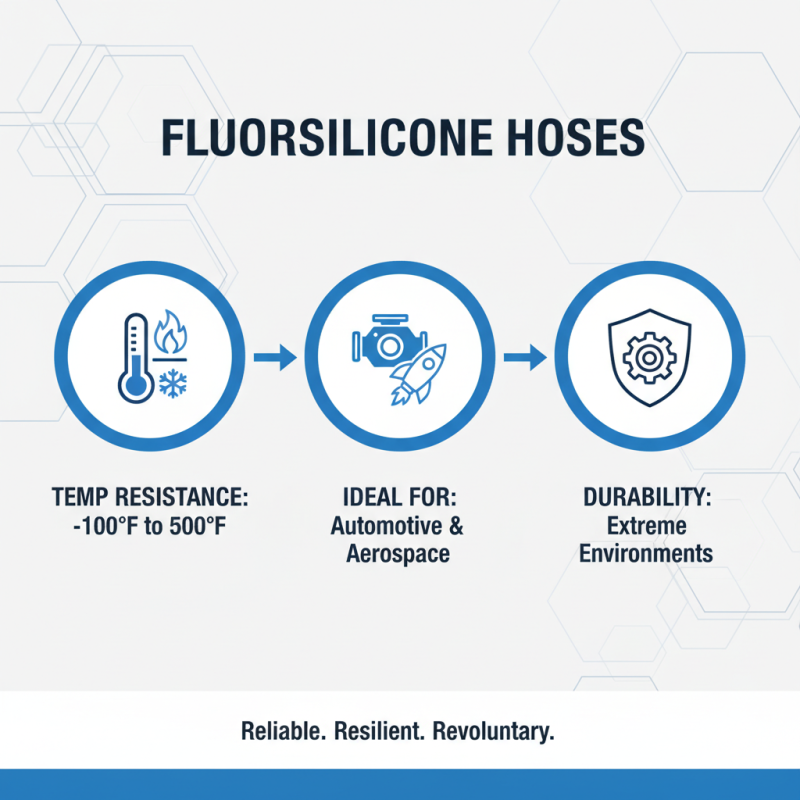

Fluorosilicone hoses are unique components in various industries, offering remarkable features. One standout aspect is their excellent resistance to extreme temperatures. They can handle a wide range, from very low to extremely high temperatures. This makes them ideal for automotive and aerospace applications, where conditions can be severe. Their ability to withstand harsh environments increases their reliability.

Another key benefit of fluorosilicone hoses is their resistance to chemicals. They can tolerate various fluids, including oil and certain solvents. This characteristic is crucial for industries that deal with aggressive substances. However, it is essential to note that not all chemicals are safe. Users need to evaluate compatibility carefully.

Moreover, fluorosilicone hoses boast flexibility and durability. They can bend and flex without compromising their integrity. This adaptability allows for easier installation in tight spaces. Despite these advantages, users may find higher costs compared to traditional materials. Evaluating cost versus performance is necessary for making informed choices.

Fluorosilicone hoses are widely used in various industries due to their excellent heat resistance and durability. These hoses are especially effective in environments that involve exposure to fuels, oils, and high temperatures. In aerospace applications, they play a crucial role in fuel systems. According to a recent industry report, the aerospace sector is projected to grow by 5% annually, increasing the demand for reliable components like fluorosilicone hoses.

In automotive manufacturing, fluorosilicone hoses are also common. They are often used in fuel delivery systems and in engines where high performance and reliability are paramount. Reports suggest that the automotive sector will require more advanced materials to meet stricter environmental standards. This makes fluorosilicone hoses an excellent choice as they resist degradation from fuel and oil exposure.

Tip: Always check the specifications of fluorosilicone hoses for specific applications. Not all hoses are created equal. Poor quality materials can lead to failures.

In the chemical processing industry, fluorosilicone hoses are vital. They are resistant to many chemicals, making them safe for transporting various substances. However, there’s a risk of over-reliance on this material. Ensure regular inspections and maintenance to prevent degradation that can occur over time.

Tip: Regularly assess the working conditions for your hoses. Environmental factors can influence their lifespan significantly.

When working with fluorosilicone hoses, proper installation and maintenance are essential for optimal performance. Always inspect the hose for any visible damage before installation. Look for cracks, abrasions, or any signs of wear. If found, address these issues before use. Sometimes, what seems minor can lead to bigger problems later.

During installation, ensure that the hose is not twisted or kinked. These misalignments can cause pressure buildup or leaks. It's crucial to use the correct fittings. Improper connections might lead to failures under pressure. Tightening should be done carefully. Too much torque can damage the hose, leading to premature failure.

Regular maintenance is key for longevity. Check the hose periodically for any signs of wear or leaks. Keeping the connection points clean will help prevent issues. Some users overlook the importance of routine checks. It might seem tedious, but it saves time and resources in the long run. Over time, environmental factors may also degrade the hose’s material. Pay attention to these factors to extend the life of the hose.

Fluorosilicone hoses are specialized components designed to withstand extreme environmental conditions. They excel in applications involving chemicals, fuels, and high temperatures. When compared to traditional silicone hoses, fluorosilicone hoses offer superior resistance to automotive fluids and volatile organic compounds. This makes them a preferred choice in aerospace and automotive sectors, where safety is paramount.

In terms of chemical resistance, fluorosilicone performs remarkably well. According to industry studies, it can endure temperatures ranging from -65°F to +400°F. This is significantly higher than standard rubber hoses, which typically function well only up to 250°F. The flexibility of fluorosilicone helps in installations with tight bends, where rigid hoses fail. However, their cost is a downside. They can be up to 40% more expensive than other materials, making budget-conscious choices difficult for some customers.

When evaluating the performance, the durability of fluorosilicone hoses is notable. They boast a lifespan that can exceed 10 years with proper care. Yet, improper handling during installation can lead to early degradation. This is often overlooked, leading to costly replacements. Additionally, while they resist a wide range of chemicals, some aggressive substances can still cause issues. This is an area that demands further investigation and awareness from users.

| Hose Type | Material | Temperature Range (°F) | Chemical Resistance | Flexibility | Common Applications |

|---|---|---|---|---|---|

| Fluorosilicone Hose | Fluorosilicone Rubber | -65 to 400 | Excellent | Good | Aerospace, Automotive |

| Silicone Hose | Silicone Rubber | -65 to 500 | Good | Excellent | Automotive, Food Processing |

| Rubber Hose | Natural or Synthetic Rubber | -40 to 180 | Moderate | Good | Industrial, HVAC |

| PTFE Hose | PTFE | -320 to 500 | Excellent | Fair | Chemical Transfer, Aerospace |

| PVC Hose | Polyvinyl Chloride | -20 to 150 | Poor | Good | Water Transfer, Construction |