In the realm of food processing and handling, maintaining safety and hygiene is paramount. One integral component that supports these standards is the Food Grade Silicone Hose. This specialized hose is engineered to meet strict regulatory requirements, ensuring that it is safe for direct contact with food products. According to a recent report from the Food and Drug Administration (FDA), materials used in food preparation and processing must adhere to stringent safety standards to prevent contamination and protect public health. The Food Grade Silicone Hose not only complies with these regulations but also offers flexibility, durability, and resistance to extreme temperatures, making it an ideal choice for various applications in the food industry.

Furthermore, the global food industry is projected to reach $3 trillion by 2024, emphasizing the increasing demand for safe and efficient food handling solutions. The use of Food Grade Silicone Hose in food production systems enhances operational efficiency while safeguarding against potential health risks associated with inferior materials. As consumers become more aware of the importance of food safety, the role of high-quality components like the Food Grade Silicone Hose becomes ever more critical in fostering trust and confidence in food products. Prioritizing such materials can significantly reduce the risk of contamination, ensuring that food reaches the market in a safe and wholesome state.

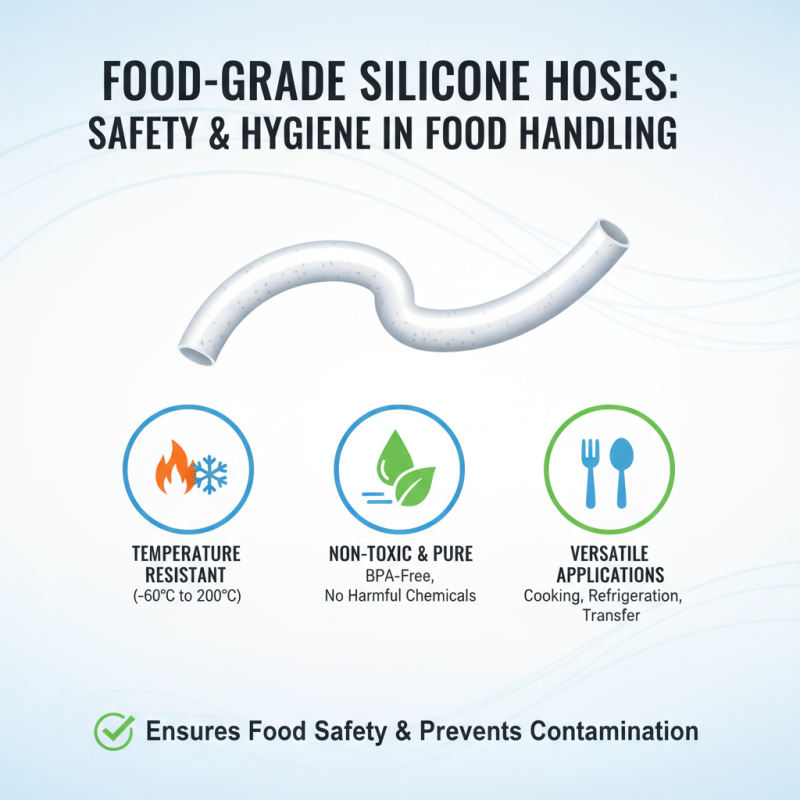

Food grade silicone hose is specifically designed for applications that involve direct contact with food products. These hoses are made from high-quality silicone that meets stringent safety and health regulations, ensuring they do not leach harmful substances. One of the key characteristics that set food grade silicone apart is its ability to withstand a wide range of temperatures, making it suitable for both hot and cold food items. Additionally, this type of silicone is resistant to moisture, staining, and microbial growth, which are essential qualities for maintaining hygiene in food handling environments.

Tips for choosing the right food grade silicone hose include ensuring it meets FDA standards and checking its temperature tolerance specifications. It is also beneficial to look for hoses that are flexible yet sturdy enough to handle the rigors of food processing without kinking or breaking. Regular cleaning and maintenance are crucial to prevent buildup and contamination, so consider selecting hoses that are easy to clean or are dishwasher safe.

When it comes to installation, make sure to use appropriate fittings that are also food grade to maintain a safe connection between the hose and food equipment. Properly securing connections will help prevent leaks, ensuring a safe environment for food handling and processing.

| Characteristic | Description |

|---|---|

| Material | Made from 100% food grade silicone, free from harmful chemicals. |

| Temperature Resistance | Can withstand temperatures ranging from -60°C to 200°C (-76°F to 392°F). |

| Flexibility | Highly flexible and easy to handle, allows for custom applications. |

| Durability | Resistant to cracking and UV light, ensuring long service life. |

| Non-Toxic | Does not contain BPA, phthalates, or other toxic substances, safe for food contact. |

| Applications | Used in kitchens, food processing industries, and laboratory settings. |

| Cleaning | Easy to clean, dishwasher safe, and does not retain odors. |

Food grade silicone hoses are crucial in the food industry due to their unique properties that ensure safety and hygiene during food handling. One of the primary features of these hoses is their high resistance to temperature extremes. They can withstand both high heat during cooking processes and low temperatures for refrigeration, making them versatile for various applications. Additionally, food grade silicone hoses are non-toxic and free of harmful chemicals, which prevents contamination of food products.

Another key property of food grade silicone hoses is their flexibility and durability. They can bend and twist without breaking, facilitating installation in tight spaces and during complex processes. Their resilience to wear and tear leads to a longer lifespan compared to other materials, reducing the need for frequent replacements. Furthermore, these hoses are easy to clean and maintain, ensuring that they meet strict hygiene standards required in food processing environments. Overall, the combination of safety, flexibility, and durability makes food grade silicone hoses an essential component in the food industry.

Food grade silicone hoses are increasingly recognized for their crucial role in

safe food handling, as they meet stringent health and safety regulations.

Unlike standard hoses, food grade silicone is manufactured without harmful chemicals, ensuring that no toxins leach into food products.

According to a report by the Food and Drug Administration (FDA), materials used in food contact applications must comply with strict safety standards.

Food grade silicone hoses typically conform to these stringent guidelines, making them ideal for culinary applications.

The benefits of using food grade silicone hoses extend beyond safety. Their durability and flexibility enable them to withstand

extreme temperatures, ranging from -80°F to 500°F, making them suitable for various cooking processes, from boiling to freezing.

Additionally, silicone's non-reactive nature prevents flavors and odors from being absorbed, maintaining the integrity of food items.

The silicone hoses' resistance to mold and bacteria growth also enhances hygiene, contributing to a safer food processing environment.

The Global Food Safety Initiative highlighted that the reduction of contamination risks is vital in food handling, and using food grade materials like silicone hoses significantly aids in achieving this goal.

Food grade silicone hoses are essential components in various food handling applications, and they must adhere to specific industry standards and certifications to ensure safety and compliance. These standards, such as FDA approval and NSF certification, guarantee that the materials used in manufacturing these hoses do not leach harmful substances into food products. The silicone must be non-toxic, able to withstand high temperatures, and resistant to microbial growth, ensuring the highest level of safety for consumers.

Moreover, industry certifications serve as a benchmark for quality, reliability, and hygiene. Organizations such as the American National Standards Institute (ANSI) and the European Union standards are pivotal in evaluating and approving food grade silicone products. These certifications are crucial for manufacturers, providing assurance that the materials used in food processing and handling meet stringent safety guidelines. Utilizing hoses that meet these certifications not only enhances the safety of food products but also helps businesses avoid potential liabilities associated with food contamination.

Food grade silicone hoses are increasingly recognized for their critical role in food processing and storage. These hoses are designed to meet stringent health and safety standards, making them essential for transporting food products, liquids, and ingredients. According to a report from the Food Safety and Inspection Service (FSIS), improper handling of food products can lead to contamination, with studies showing that nearly 48 million Americans suffer from foodborne illnesses each year. Utilizing food grade silicone hoses can significantly reduce such risks due to their non-toxic, non-reactive properties that prevent leaching of harmful substances.

In the realm of food processing, food grade silicone hoses are widely used in various applications, including beverage production, dairy processing, and bakery operations. Their flexibility and resistance to extreme temperatures and chemicals ensure durability and reliability in these environments. Additionally, the silicone material is compliant with FDA regulations, making it safe for direct contact with food. Industry reports indicate that the demand for food grade silicone products is projected to grow at a CAGR of over 4% through 2025, reflecting the increasing emphasis on food safety and hygiene standards across the food industry. Thus, the application of food grade silicone hoses is indispensable in facilitating safe and efficient food handling practices, ultimately protecting consumer health.