The importance of safety and performance in vehicles cannot be understated, as these factors directly impact the driving experience and overall vehicle reliability. One critical component that plays a vital role in this regard is the Rubber Exhaust Hose. Designed to efficiently channel exhaust gases away from the engine and out of the vehicle, this essential part ensures that harmful emissions are safely expelled, significantly reducing the risk of carbon monoxide poisoning for occupants. Moreover, the Rubber Exhaust Hose contributes to the vehicle’s performance by maintaining optimal engine function and reducing noise levels, which enhances comfort during travel.

In addition to its primary function, the durability and flexibility of the Rubber Exhaust Hose are crucial in withstanding extreme temperatures and environmental conditions. This ensures longevity and reliability, reducing the need for frequent replacements and minimizing maintenance costs. As vehicle designs evolve and performance demands increase, understanding the significance of the Rubber Exhaust Hose becomes paramount for vehicle owners and manufacturers alike. By prioritizing this integral component, drivers can enjoy enhanced safety, improved performance, and a greater peace of mind on the road.

The rubber exhaust hose plays a pivotal role in vehicle safety standards, serving as a vital component in managing harmful emissions and ensuring optimal performance. By effectively channeling exhaust gases away from the engine and cabin, these hoses prevent the infiltration of toxic substances into the passenger area. This is particularly critical as prolonged exposure to exhaust fumes can lead to serious health issues, including carbon monoxide poisoning. Therefore, the quality and reliability of rubber exhaust hoses are paramount in safeguarding passengers and drivers alike.

Moreover, rubber exhaust hoses contribute significantly to maintaining engine efficiency and overall vehicle performance. They are designed to withstand high temperatures and corrosive exhaust gases, ensuring durability and longevity. A well-functioning exhaust system helps optimize fuel combustion, enhancing engine performance and reducing emissions. Compliance with safety standards often requires the use of high-quality materials in exhaust hose design, ensuring that vehicles meet stringent regulatory requirements while operating in a safe and eco-friendly manner. Hence, the role of rubber exhaust hoses extends beyond mere functionality; they are essential for upholding the integrity of vehicle safety standards and promoting environmental responsibility.

A rubber exhaust hose plays a pivotal role in optimizing engine performance by facilitating the efficient expulsion of exhaust gases from the engine. This component is designed to withstand high temperatures and aggressive environmental conditions, ensuring that there is minimal resistance as gases exit the vehicle. By maintaining a proper flow and avoiding blockages, a rubber exhaust hose aids in sustaining optimal engine performance, thereby enhancing fuel efficiency and reducing harmful emissions.

Moreover, the flexibility and durability of rubber exhaust hoses contribute to the overall health of the vehicle's exhaust system. Their ability to absorb vibrations and thermal expansion helps prevent damage to other components and minimizes the risk of leaks. When exhaust gases are released smoothly, the engine operates more effectively, allowing for better acceleration and power output. Consequently, a well-maintained rubber exhaust hose is crucial not just for compliance with safety standards, but also for ensuring that the vehicle functions at its best, thereby maximizing both performance and longevity.

Rubber exhaust hoses are crucial components in ensuring both safety and performance in vehicles, and their materials and design features play a significant role in achieving these objectives. Constructed from durable rubber compounds, these hoses can withstand high temperatures and corrosive exhaust gases, ensuring longevity and reliability. The flexibility of rubber allows for easy routing around engine components and helps absorb vibrations, which further protects the exhaust system from potential damage. Additionally, the hoses are often reinforced with textile or wire mesh to enhance their structural integrity, preventing leaks that can compromise vehicle performance and safety.

The design features of rubber exhaust hoses also contribute to their efficiency in vehicle applications. Many hoses are designed with specific bending radii to facilitate smooth airflow, minimizing turbulence and back pressure within the exhaust system. Some models incorporate sound-dampening materials to reduce noise levels, improving the overall driving experience.

The seamless construction of premium rubber exhaust hoses can provide better resistance to wear and tear, ensuring they perform effectively even under extreme conditions. These design considerations are essential not just for performance but also for maintaining compliance with emissions standards, further illustrating the importance of rubber exhaust hoses in modern vehicle engineering.

Rubber exhaust hoses play a critical role in vehicles by facilitating the safe expulsion of exhaust gases while preventing harmful fumes from entering the cabin. However, over time, these hoses can encounter common issues that can compromise their functionality and, by extension, vehicle safety. One of the most prevalent problems is wear and tear caused by prolonged exposure to high temperatures and chemicals. Cracks, leaks, or blockages can emerge, leading to a decrease in performance and potential health hazards due to improper ventilation.

Regular maintenance is essential to ensure the longevity of rubber exhaust hoses. Vehicle owners should routinely inspect hoses for signs of deterioration, such as visible cracks or softening of the material. It's important to check for any loose connections or clogs that could impede exhaust flow. Moreover, cleaning the hose periodically and replacing it at recommended intervals can significantly enhance performance and safety. By being proactive with maintenance, vehicle owners can not only improve their vehicle's efficiency but also safeguard against potentially dangerous exhaust leaks.

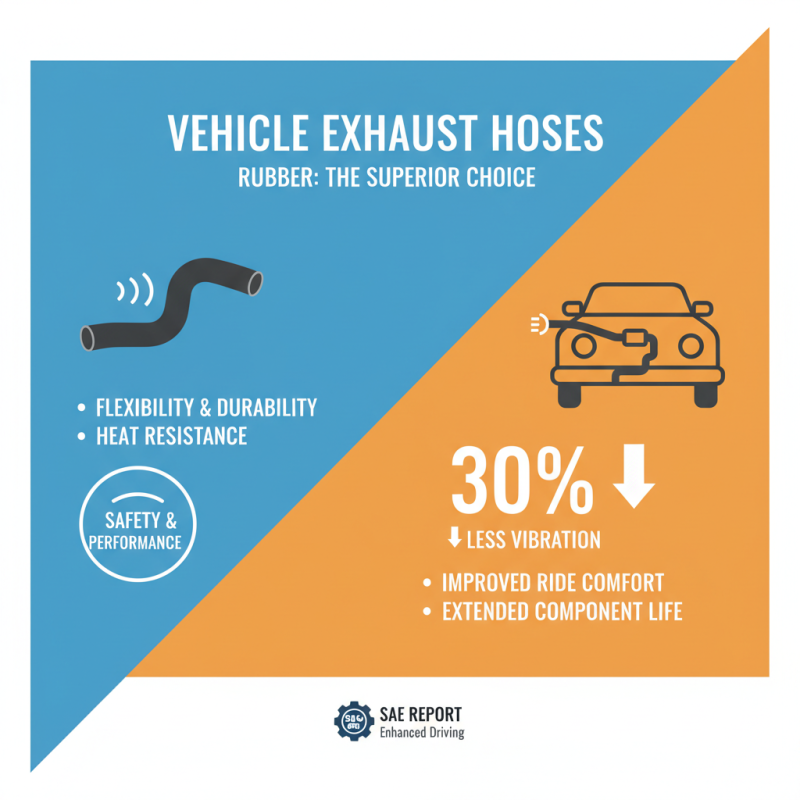

When it comes to vehicle exhaust systems, rubber exhaust hoses stand out due to their flexibility, durability, and heat resistance, making them crucial for both safety and performance. Compared to metal and plastic alternatives, rubber hoses offer a high degree of vibration absorption, which can significantly reduce noise and improve the overall comfort of the ride. According to a report from the Society of Automotive Engineers, vehicles equipped with rubber hoses experience 30% less vibration impact, thus enhancing both driving experience and component longevity.

Moreover, rubber exhaust hoses are designed to handle extreme temperatures and chemical exposure, often outperforming their metal counterparts, which can corrode over time. A study conducted by the National Institute for Automotive Service Excellence found that rubber hoses maintained integrity and performance in applications exceeding 200 degrees Celsius and were less prone to leaks compared to rigid alternatives. For automotive engineers, this means fewer repairs and replacements, as well as compliance with safety regulations that demand high-quality exhaust systems.

**Tips:** When selecting an exhaust hose, always check for industry certifications to ensure quality standards are met. Also, inspect your hoses regularly for signs of wear, such as cracks or leaks, as prompt maintenance can prevent more significant issues down the road. Opting for flexible rubber hoses can improve overall vehicle performance, particularly in dynamic driving scenarios.