As the agricultural and industrial sectors continue to evolve, the need for efficient and reliable equipment is ever more crucial. Among these essential tools, the Rubber Suction Hose stands out, providing myriad benefits for various applications. Industry expert Dr. Jane Thompson, a leading authority on agricultural equipment, states, "The versatility and durability of the Rubber Suction Hose make it an indispensable asset in both farming and industrial processes." This statement underscores the significant role that these hoses play in enhancing productivity and operational efficiency.

In agriculture, Rubber Suction Hoses facilitate the transfer of liquids, slurries, and other materials, proving vital for irrigation and drainage systems. Their robust design ensures they can withstand the demanding conditions often encountered in fieldwork. Similarly, in industrial settings, these hoses are used to manage bulk fluids, making them essential for tasks such as waste removal and chemical handling. With the capacity to resist abrasion and temperature variations, Rubber Suction Hoses serve as a reliable solution for these rigorous applications, reinforcing their status as a key component in both sectors.

Rubber suction hoses play a critical role in various sectors, particularly in agriculture and industry, due to their versatility and durable performance. In agriculture, these hoses are primarily used for transporting liquids such as water and fertilizers. According to a report from the Agricultural Industries Confederation (AIC), effective irrigation methods, which often employ suction hoses, can increase crop yield by up to 20%. The elasticity and resilience of rubber hoses allow them to handle varying pressures while maintaining a strong seal, making them ideal for transferring agricultural inputs efficiently.

In industrial applications, rubber suction hoses are essential for the safe handling of various materials, including slurries, chemicals, and food products. The Rubber Manufacturers Association indicates that industrial rubber hose consumption is projected to grow at a rate of 4% annually. This growth is driven by the increasing demand for lightweight, flexible, and resistant hoses that can be used in manufacturing processes. Their ability to withstand harsh environments and chemicals makes them invaluable in sectors such as mining and food processing, where compliance with strict safety and quality standards is paramount. As industries continue to evolve, the applications of rubber suction hoses are expected to expand, driving innovation and efficiency across the board.

| Application | Benefits | Material Used | Typical Diameter | Working Pressure |

|---|---|---|---|---|

| Irrigation Systems | Durable and flexible, resistant to UV and ozone | EPDM or NBR | 1" - 4" | 30-50 psi |

| Liquid Fertilizer Handling | Chemical resistant, prevents contamination | NBR (Nitrile Rubber) | 2" - 6" | 45-60 psi |

| Water Transfer | Lightweight, easy to handle, non-toxic | Natural Rubber | 1.5" - 3" | 20-40 psi |

| Dust Control | Helps minimize dust particles, reduces air pollution | EPDM | 3" - 5" | 30 psi |

| Food and Beverage Processing | FDA compliant, safe for food contact | Silicone Rubber | 1" - 2" | 15-25 psi |

| Chemical Transfer | High resistance to a wide range of chemicals | Hypalon or Viton | 2" - 4" | 70 psi |

| Pumping Systems | Efficient suction and discharge for fluids | NBR | 1.5" - 3" | 50 psi |

| Dewatering Applications | Effective for removing excess water | PVC or Rubber | 4" - 8" | 25-35 psi |

| Fire Fighting | Resistant to heat and abrasion | EPDM | 1.5" - 4" | 80 psi |

Rubber suction hoses play a crucial role in enhancing operational efficiency in both agricultural and industrial applications. These versatile hoses are designed to withstand a variety of environmental conditions, providing reliable performance in the transport of liquids, slurries, and other materials. According to a recent report by the Agricultural Hose Association, the use of rubber suction hoses can reduce material handling time by up to 30%, significantly improving productivity in farming operations.

One of the key benefits of rubber suction hoses is their durability. They are capable of operating in extreme temperatures and are resistant to wear, which leads to decreased maintenance costs. The flexibility and resilience of rubber hoses allow for easier handling and routing around obstacles, making them ideal for complex agricultural setups. Additionally, data from the Industrial Hose Manufacturers Association indicates that using rubber suction hoses can lower operational downtime due to their superior resistance to abrasives and chemicals compared to standard hoses. This translates to more efficient workflows and increased uptime—essential in today’s fast-paced agricultural and industrial landscapes.

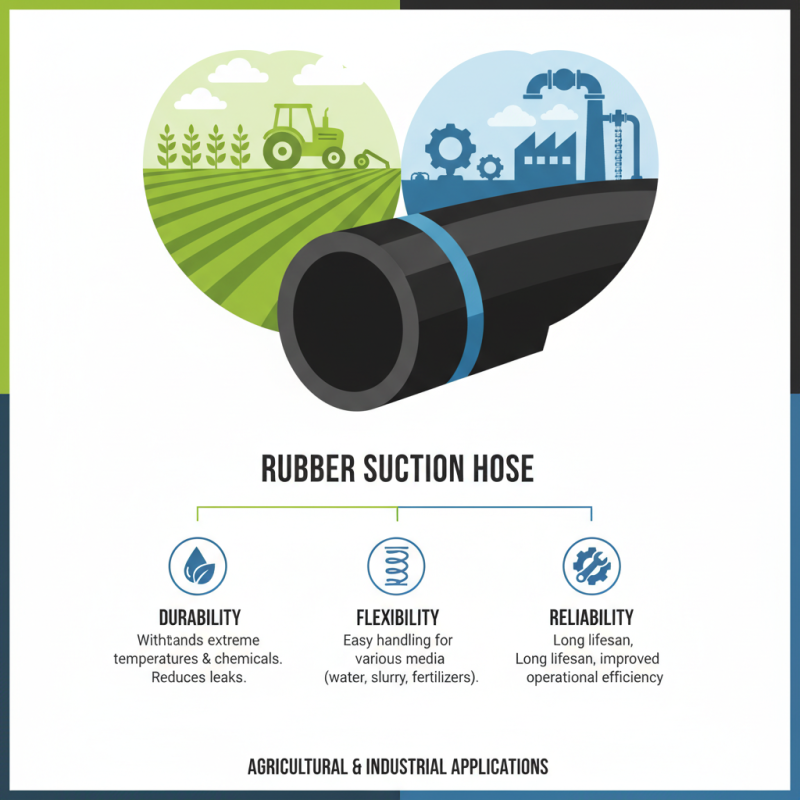

Rubber suction hoses are notable for their exceptional durability and flexibility, making them indispensable in both agricultural and industrial applications. Constructed from high-quality rubber, these hoses are designed to withstand harsh environmental conditions, including extreme temperatures and exposure to chemicals. Their robust construction ensures they can handle various media, from water and slurry to fertilizers and other agricultural products. This resilience not only prolongs the life of the hose but also reduces the risk of leaks and ruptures, thereby enhancing operational efficiency.

Flexibility is another significant feature of rubber suction hoses, which allows for easy handling and maneuverability. Unlike rigid piping systems, these hoses can bend and stretch without compromising their integrity, making them ideal for dynamic environments where movement and adjustments are frequent. This adaptability is particularly beneficial in agricultural settings, where hoses are often moved around fields and farms. Additionally, the smooth interior surface of rubber hoses minimizes friction, facilitating better flow rates and reducing energy costs associated with pumping systems. Overall, the combination of durability and flexibility makes rubber suction hoses a practical choice for various tasks in agriculture and industry.

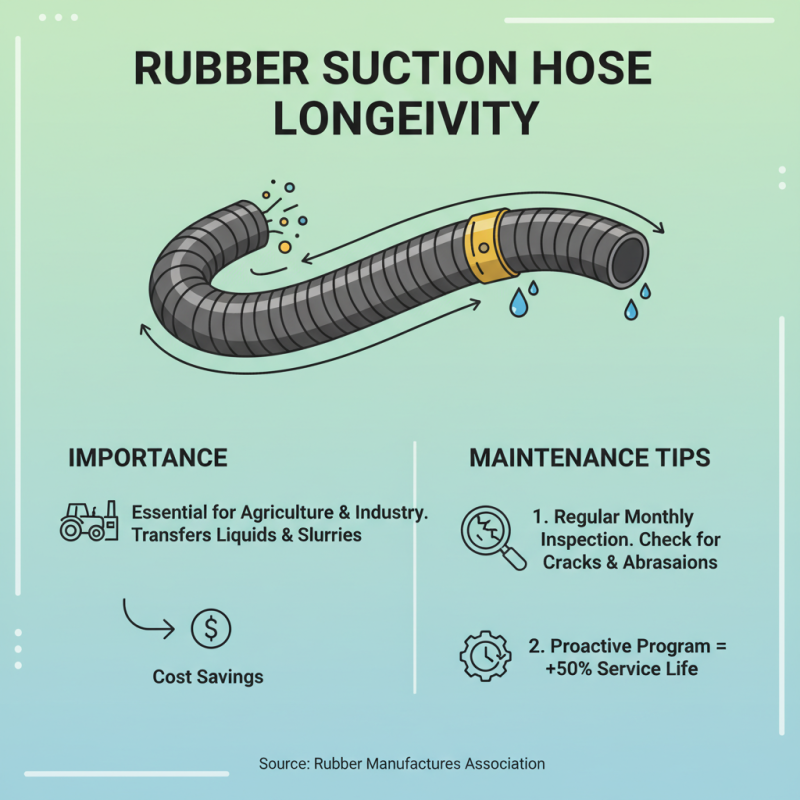

Rubber suction hoses are essential in both agricultural and industrial applications, providing effective and efficient transfer of liquids and slurries. However, the longevity of these hoses can be significantly influenced by proper maintenance practices. Regular inspection is crucial; it is recommended to check hoses for signs of wear and tear, such as cracks or abrasions, at least once a month. According to the Rubber Manufacturers Association, a proactive maintenance program can extend the service life of rubber hoses by up to 50%, which can lead to substantial cost savings for businesses reliant on these essential tools.

Additionally, proper storage of rubber suction hoses is vital in ensuring their durability. Hoses should be kept away from direct sunlight and extreme temperatures, which can degrade their material over time. The American Society for Testing and Materials suggests maintaining a controlled environment to prevent premature aging of rubber products. Furthermore, it’s important to flush hoses regularly to avoid the build-up of residues, which can contribute to internal degradation. Employing these maintenance strategies can significantly enhance efficiency and reliability in various agricultural and industrial settings, ensuring operations run smoothly without unexpected interruptions due to equipment failure.

When considering the efficiency and performance of hoses in agricultural and industrial settings, rubber suction hoses stand out through their distinctive attributes. Unlike plastic or metal hoses, rubber suction hoses offer flexibility and resilience, making them ideal for handling various materials and liquid transfers. Their ability to endure extreme temperatures and resist wear ensure longevity and reliability, which is crucial in high-demand environments. Furthermore, rubber hoses provide better suction capabilities compared to many alternatives, allowing for effective transfer of both liquids and solids without the risk of collapse or kinking that other hose materials might present.

In contrast, metal hoses, while durable, often lack the flexibility needed for dynamic applications. They also tend to be heavier, which could pose challenges during handling. On the other hand, plastic hoses can be lightweight and easy to maneuver, but they typically fall short in terms of durability and resistance to environmental factors. The comparative analysis reveals that rubber suction hoses are not only versatile but also more efficient for a wider range of applications due to their superior properties, making them an essential choice when reliability and performance are paramount.