A Silicone Hose Kit is an essential component for many automotive and industrial applications. These kits typically include high-quality silicone hoses designed for various purposes. They are known for their durability and heat resistance. However, many users may wonder if they truly need a Silicone Hose Kit.

One key advantage is the improved performance they offer. Silicone hoses can withstand extreme temperatures better than standard rubber hoses. They also provide better flexibility and longevity, which can reduce maintenance. Yet, some may find them too expensive initially. This raises the question of whether the investment is worth it.

Additionally, using a Silicone Hose Kit can enhance the appearance of your engine bay. Bright colors and sleek designs can transform the look of your vehicle. But do these aesthetic benefits justify the cost? It’s a tough call for many enthusiasts. In the end, considering both performance and visual appeal will lead to better decisions.

A silicone hose kit typically includes various silicone hoses designed for automotive and industrial applications. These hoses are known for their durability and flexibility. They can withstand high temperatures and pressures, making them ideal for engines and cooling systems. The composition of a silicone hose kit usually consists of high-grade silicone material, which adds to its resilience.

In addition to silicone hoses, the kit often contains clamps and connectors. These components help secure hoses in place, preventing leaks. The hoses come in different sizes and shapes to fit specific needs. While silicone hoses are proficient in many areas, they may not be suitable for every situation. Their color options and flexibility can be appealing, yet some might question their effectiveness under certain conditions.

Choosing a silicone hose kit can benefit your project, but it's essential to evaluate your requirements. Some users find that not every hose lasts as long as expected. Addressing installation issues is vital. Ensuring proper fit and securing each component can help maximize performance. This attention to detail can make a significant difference in functionality.

When it comes to automotive performance, a silicone hose kit stands out. These kits are designed to replace traditional rubber hoses, offering numerous benefits. Silicone materials resist heat much better than rubber. This is crucial for high-performance engines. They can withstand extreme temperatures and pressures. This makes them ideal for racing and modified vehicles.

Tips: Always check the compatibility of silicone hoses with your vehicle's system. Incompatible materials can lead to leaks or failures. Installation may require special tools. Be prepared for some adjustments.

Using silicone hoses also means better durability. They resist cracking and aging. This can save you time on maintenance. However, some people overlook the need for regular checks. Small leaks may lead to bigger problems over time. Not all silicone hoses are created equal. Always do your research before purchasing.

Another advantage is the vibrant colors available. A silicone hose kit can enhance the look of your engine bay. Some people prioritize aesthetics over function. That's not always wise. Performance should always come first. However, the right hose kit can offer both style and substance. Make sure to evaluate your needs before choosing a kit.

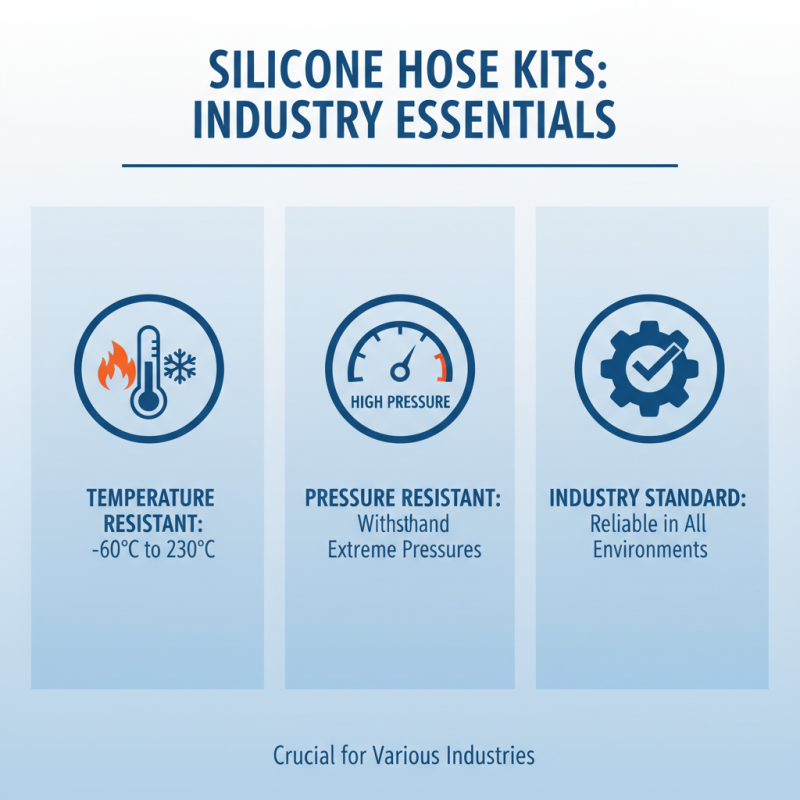

Silicone hose kits are becoming essential in various industries. These hoses can withstand extreme temperatures and pressures. Understanding industry standards for silicone hoses is crucial. They often have temperature ratings ranging from -60°C to 230°C. This means they perform reliably in both hot and cold environments.

Pressure ratings are equally important. Many silicone hoses can handle pressures of up to 2 bar, depending on the design. When selecting a hose kit, it’s essential to consider the specific needs of your application. Are you working with high heat or high pressure? Make sure the hoses meet those requirements.

Tips: Always verify the specifications before purchase. Not all silicone hoses are created equal. A mismatch can lead to failure. Regularly inspect hoses for wear and tear. Feel free to replace old hoses even if they look fine. Small cracks or deterioration can lead to severe problems later.

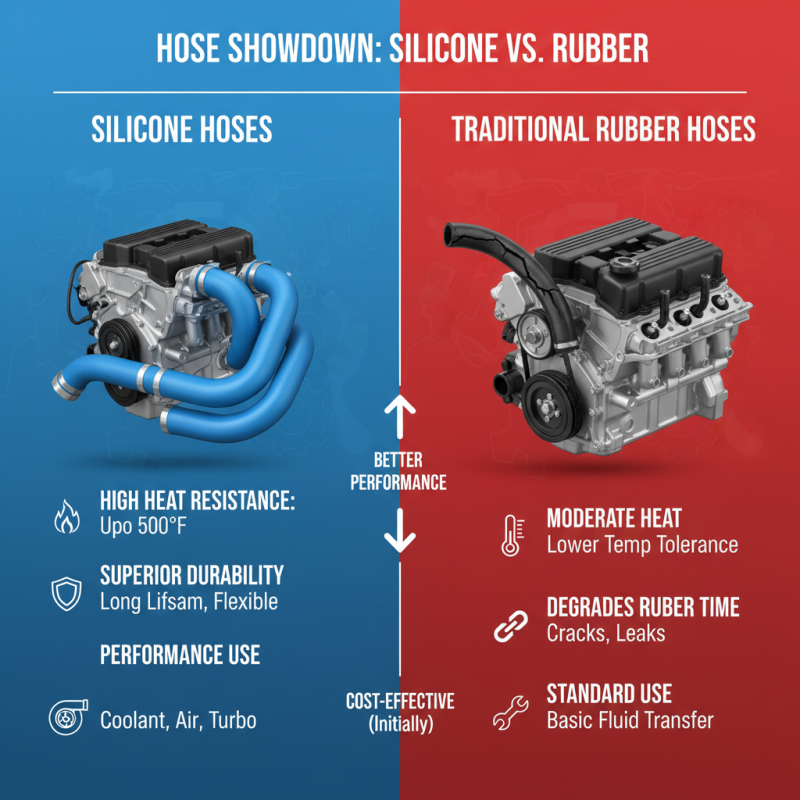

Silicone hoses and traditional rubber hoses serve similar purposes, but they differ significantly in performance and durability. Silicone hoses can withstand higher temperatures, making them ideal for high-performance engines. They are often used in applications involving coolant, air intake, and turbocharging. In contrast, traditional rubber hoses may degrade faster under extreme conditions, leading to potential leaks or failures.

The flexibility of silicone hoses is another advantage. They are more resistant to cracking and can withstand a wider range of operating conditions. This flexibility also makes installation easier. However, these hoses can be more expensive than traditional rubber options, which may deter some users. Despite their cost, the long-term benefits often outweigh initial pricing.

Yet, silicone hoses are not perfect. They can sometimes be too soft, leading to collapsed hoses under certain pressures. Users need to consider their specific requirements when choosing between silicone and rubber. The decision should factor in not just cost, but also performance needs and long-term reliability. The choice can be complex, prompting reflection on the best materials for different projects.

Silicone hose kits have become essential in the world of performance vehicles. These kits are widely used in cooling systems, intake systems, and exhaust systems. Their versatility meets the demands of high-performance applications. According to a recent report by the Specialty Equipment Market Association (SEMA), silicone hoses can withstand extreme temperatures and pressures, making them preferable over traditional rubber hoses.

In cooling systems, silicone hoses maintain efficiency better than rubber counterparts. They resist heat degradation and have a longer lifespan. For instance, a silicone hose can endure temperatures up to 350°F, while rubber hoses often fail at 200°F. This temperature resistance is critical in motorsports, where engine performance is paramount. The automotive industry has noted a drop in highway vehicle failures by up to 15% when silicone hoses are employed in cooling systems.

Intake systems also benefit from silicone hose kits. Enhanced airflow allows for improved engine performance. Performance data shows that increasing air intake by even 10% can boost power output significantly. Some enthusiasts report enhancements in throttle response and fuel efficiency. However, installing silicone hoses may require more thoughtful planning, as the correct sizing and routing are vital. A poorly fitted hose can lead to lower performance outcomes.