Choosing the right silicone hump hose can make a significant difference in performance. These hoses are flexible and durable, making them ideal for various applications. Understanding the options available ensures you make an informed decision.

Silicone hump hoses come in different sizes and shapes. This variety allows them to fit specific systems in vehicles and machinery. When selecting one, consider factors like temperature resistance and pressure ratings. It’s crucial to match these specifications with your needs to avoid potential issues.

While silicone hump hoses offer great benefits, imperfections exist. Not every hose will perform flawlessly. Some users find they don't always fit perfectly. Measuring your system accurately is essential to avoid installation challenges. Reflecting on your choices ensures you get the best possible product for your application.

Silicone hump hoses are designed for a variety of applications. They are widely used in automotive engines and other machinery. These hoses are flexible and durable, making installation easier in tight spaces. Their ability to handle high temperatures is a significant feature. Silicone can withstand extreme conditions that standard rubber hoses cannot.

One interesting aspect of silicone hump hoses is their color options. They come in various colors, adding aesthetic value to your machinery. However, choosing the right color can affect heat absorption. Dark colors may retain more heat. You should also consider the size; improper sizing can lead to leaks.

While silicone hoses are robust, they aren't indestructible. Misinstallation can lead to damage over time. It’s crucial to inspect them regularly for wear or tear. The right maintenance can prolong their lifespan significantly. Always remember that these hoses are part of a larger system. That means their performance impacts overall efficiency.

Silicone hump hoses come in various types, each designed for specific applications. These hoses are often used in automotive and industrial settings. They are popular due to their flexibility and heat resistance. One common type is the standard silicone hump hose, which offers enhanced durability. It's ideal for connecting parts in turbo systems.

Another variation is the multi-layered silicone hump hose. This type features additional layers that improve strength and pressure resistance. It is crucial for high-performance vehicles where turbo pressure can be significant. In contrast, there are also low-temperature silicone hoses. These are perfect for colder environments. They remain flexible even in extreme conditions.

When choosing a silicone hump hose, consider your specific needs. The right material can make a noticeable difference. Some hoses may not fit perfectly, which might lead to leaks. Take the time to measure before purchasing. This detail can prevent larger issues down the road. A perfect fit is vital for performance and longevity.

| Type | Size (inches) | Temperature Range (°F) | Pressure Rating (psi) | Application |

|---|---|---|---|---|

| Straight Hose | 3 | -76 to 500 | 15 | Cooling Systems |

| Reducer | 2-3 | -40 to 400 | 20 | Turbo Applications |

| Elbow Hose | 90° | -60 to 300 | 25 | Engine Bay |

| Hump Hose | 4 | -58 to 500 | 30 | High Performance |

| Anti-Vibration Hose | 5 | -40 to 300 | 10 | Heavy Machinery |

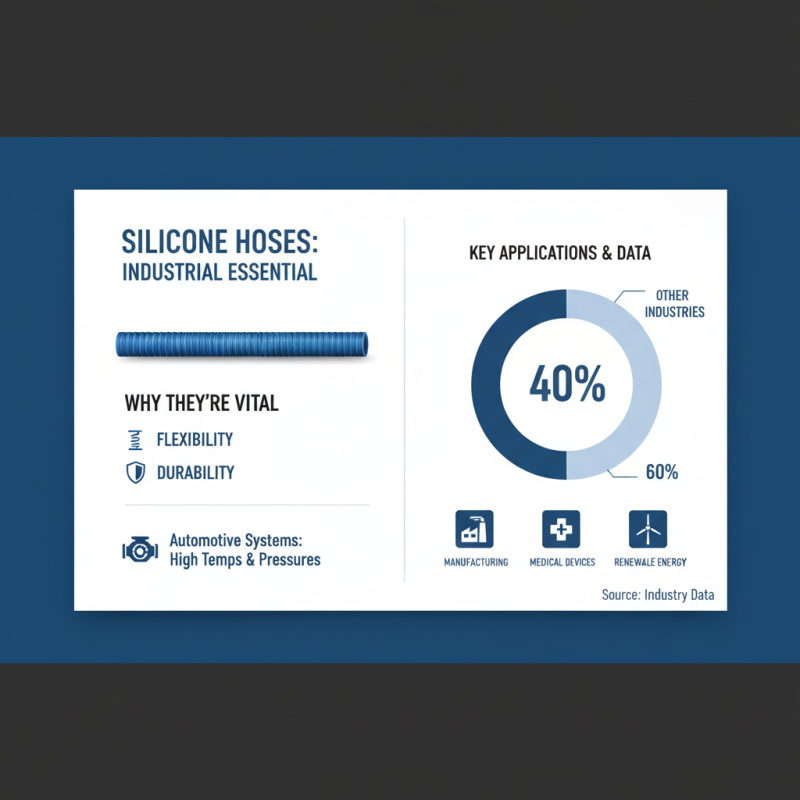

Silicone hump hoses have become vital in various industries. Their flexibility and durability make them ideal for numerous applications. In automotive systems, for example, these hoses handle high temperatures and pressures. According to industry data, the automotive sector accounts for nearly 40% of silicone hose usage.

In the aerospace industry, silicone hump hoses are essential for managing air flow in engines. These hoses can withstand extreme conditions, ensuring operational efficiency. Reports indicate that the aerospace sector's demand for silicone products has surged by over 15% in recent years. This trend highlights their critical role in safety and performance.

Tips: Always check for compatibility with your specific application. Not all silicone hoses are the same. Regular inspections can prevent failures. Investing in quality hoses pays off in the long run. Managing temperature fluctuations is crucial. It's easy to overlook, but it impacts performance significantly.

When selecting silicone hump hoses, several factors come into play. First, consider the size and dimensions. Proper fit is crucial for optimal performance. Hoses that are too large can cause leaks. Those that are too small may create blockage. Measurements should be precise to ensure a seamless fit.

Material quality is another essential aspect. Not all silicone is created equal. Some variations offer better heat resistance or durability. It’s vital to choose hoses that can withstand the specific conditions of your application. Cheaper options may save money initially, but they can lead to problems over time.

Additionally, the design of the hose matters. Some may have reinforcing layers for added strength. Others might feature unique shapes to facilitate airflow. This design affects performance. Always assess how the hose will be used. Think about potential stress points. Reflecting on these details can lead to better decision-making in the long run.

Silicone hump hoses are crucial for various applications, including automotive and industrial uses. Proper maintenance ensures longevity and performance. According to a recent industry report, silicone hoses can last up to twice as long as rubber options when cared for correctly. Regular inspections are essential to identify wear and tear. Look for cracks or bulges, which could indicate a need for replacement.

Cleaning is another critical aspect. Use mild detergent and warm water for routine cleaning. Harsh chemicals can degrade the silicone material. Experts recommend avoiding abrasive scrubbers, as they can scratch the surface. Damage can go unnoticed, leading to leaks or performance issues.

Monitoring operational temperatures and pressures is vital. Silicone can handle high temperatures, often exceeding 200°C. However, exceeding limits may lead to premature failure. Regularly review operating conditions to ensure they remain within safe ranges. Small adjustments in your system can significantly impact hose performance and lifespan. By staying proactive, users can maximize the efficiency and durability of their silicone hump hoses.