Silicone Rubber Hose is a versatile component used in various industries. This material withstands extreme temperatures and resists degradation. It is popular in automotive, medical, and food processing fields due to its safety and durability.

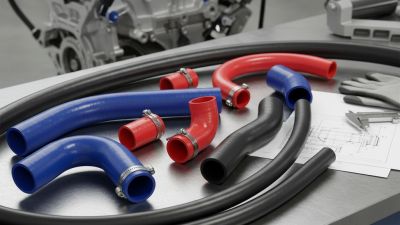

When choosing a Silicone Rubber Hose, consider the application requirements. Different sizes and shapes serve unique purposes. For instance, some hoses can handle high pressure, while others are designed for flexibility. The choices can be overwhelming, leading to potential mistakes.

Understanding how to maintain and install this hose type is crucial. Regular checks can prevent leaks and failures. However, many users neglect this aspect. Reflecting on these essential aspects can enhance performance and longevity. Knowledge truly can be power when using Silicone Rubber Hose.

Silicone rubber hoses are widely used in various applications. Their unique composition makes them ideal for high-temperature environments. Silicone rubber consists of silicone polymers, which are flexible yet durable. This material is resistant to extreme heat, chemicals, and UV exposure.

The blending of silicone with other compounds enhances its properties. Reinforcement with fibers adds strength to the hose. This combination allows the hose to withstand significant pressure. It's not just about durability; flexibility matters too. The hose can bend easily without kinking. Yet, some users find it hard to navigate in tight spaces.

Proper care is essential for the longevity of silicone rubber hoses. Regular inspection for wear and tear is important. Some might overlook this maintenance. The material can degrade under certain conditions, leading to failures. Understanding these challenges can help users utilize hoses effectively. Exploring their advantages and limitations leads to better choices in applications.

| Property | Description |

|---|---|

| Material Composition | 100% silicone rubber with a blend of polymers for elasticity and durability. |

| Temperature Resistance | Remains stable and retains elasticity in a temperature range of -60°C to 200°C (-76°F to 392°F). |

| Chemical Resistance | Resistant to water, oxygen, ozone, UV light, and many chemicals. |

| Flexibility | Highly flexible and retains its shape even after bending or twisting. |

| Applications | Used in automotive, food processing, medical devices, and other high-performance applications. |

| Color Options | Available in various colors, including transparent, red, blue, and black. |

| Durability | Long-lasting with excellent tear strength and resistance to wear and degradation. |

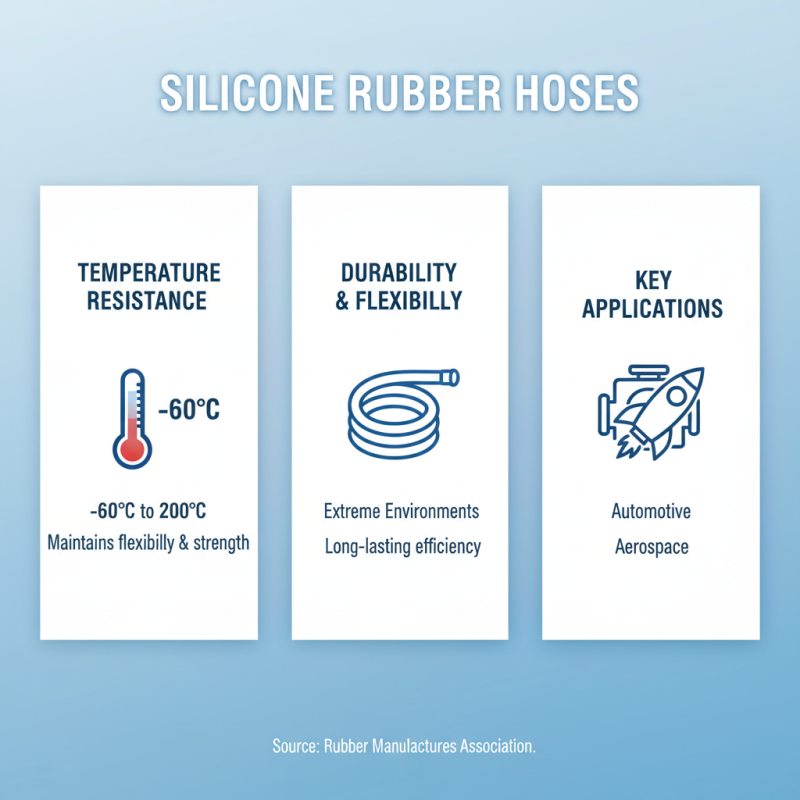

Silicone rubber hoses have become essential in various industries due to their unique properties. These hoses exhibit impressive temperature resistance, ranging from -60℃ to 200℃. This resilience makes them suitable for extreme environments. A report by the Rubber Manufacturers Association states that silicone rubber maintains its flexibility and strength even under high heat. This durability is vital in maintaining efficiency in automotive and aerospace applications.

Another remarkable feature of silicone rubber hoses is their chemical resistance. They can withstand many aggressive substances without degrading. According to industry studies, silicone hoses show excellent resistance to various oils, fuels, and solvents. This feature is particularly beneficial in the food and beverage sector, where safety and cleanliness are paramount. Still, care should be taken. Certain silicone compositions may not be suitable for all chemicals, so proper selection is essential.

Silicone rubber hoses are non-toxic and environmentally friendly. They do not leach harmful substances, making them safer for everyday use. However, their higher initial cost compared to traditional rubber may be a drawback for some users. Additionally, silicone can become less effective if exposed to UV light over time. This longevity issue highlights the importance of product selection based on application needs. As industries evolve, understanding these pros and cons allows informed decisions for various applications.

Silicone rubber hoses are versatile and widely used across various industries. They can withstand extreme temperatures, making them ideal for automotive applications. Many manufacturers rely on these hoses for coolant and heater applications. They perform well under pressure and are resistant to aging and wear. This durability can help reduce maintenance costs, but it is crucial to select the right grade of silicone for optimal performance.

In the food and beverage industry, silicone rubber hoses are also common. They are safe for food contact and can handle hot liquids without degrading. This property is vital for breweries and food processing plants. However, ensuring they meet safety standards requires regular compliance checks. Some users may overlook this aspect, assuming all silicone is compliant.

Medical applications benefit from the flexibility and sterilization capabilities of silicone hoses. They are used in devices that require precise dosing and non-reactive materials. Nonetheless, manufacturers must remain vigilant about quality control. Any lapse can lead to significant issues, compromising patient safety. Balancing cost and quality is always a challenge in this field.

Silicone rubber hoses are essential in many industrial applications. Proper maintenance can significantly extend their lifespan. Regular inspection for wear or damage is crucial. Look for cracks or fading. These signs may indicate that the hose is nearing the end of its service life.

Cleaning silicone hoses should be done carefully. Use mild soap and water. Avoid harsh chemicals. Studies show that frequent chemical exposure can degrade silicone rubber. This may lead to early failure. Rinsing thoroughly is important. Residues can affect performance over time.

Storage practices matter too. Keep hoses away from extreme temperatures and direct sunlight. A temperature range of -60°F to 200°F is ideal for most silicone hoses. If temperatures exceed this range consistently, performance can diminish. It’s wise to consider the environment where hoses are used. Ensure that they are not under constant stress. Over time, this can lead to fatigue and possible rupture.

When comparing silicone rubber hoses with other types, several factors come into play. Silicone hoses are known for their flexibility, durability, and resistance to extreme temperatures. Unlike PVC or rubber hoses, silicone does not degrade easily, making it an excellent choice for various applications. They withstand temperatures from -60°C to 220°C.

However, silicone hoses can be more expensive than their rubber counterparts. Many users may find this daunting. In contrast, rubber hoses can be a cost-effective option but tend to wear out faster and struggle in extreme conditions. PVC hoses are lightweight and inexpensive but lack the temperature resistance silicone offers.

It's essential to consider the specific needs of your project. Users must weigh the cost against the long-term benefits. Choosing a hose is not just about price; it's about ensuring reliability. Regardless of your selection, balance quality with budget. Reflecting on these aspects can lead to a more informed decision.

This chart compares the temperature resistance of different types of hoses including Silicone Rubber, PVC, Rubber, and Polyethylene. Silicone rubber hoses have superior temperature resistance, making them suitable for a variety of applications.