In the world of industrial design and manufacturing, the choice of materials can significantly impact the performance, safety, and aesthetic appeal of any project. One innovative solution that has garnered attention is the Soft Touch Silicone Hose. This versatile product offers a unique combination of flexibility, durability, and a pleasing tactile experience, making it an ideal choice for a variety of applications, from automotive to medical devices. Unlike traditional hoses, the Soft Touch Silicone Hose is designed to provide not only functionality but also comfort, ensuring ease of use in environments where user interaction is frequent.

The benefits of incorporating Soft Touch Silicone Hose into your projects extend beyond its physical properties. This type of hose exhibits excellent resistance to extreme temperatures, chemicals, and environmental factors, which enhances its lifespan and reliability. Furthermore, its soft-touch finish can improve grip and handling, reducing the risk of slippage during operation. By understanding the advantages of this innovative material, project designers can make informed decisions that elevate both the performance and user experience of their products. With the increasing demand for high-quality, user-friendly solutions, the Soft Touch Silicone Hose stands out as a pivotal component in modern project development.

Soft touch silicone hose is a unique product characterized by its soft, flexible texture which provides an enhanced user experience in various applications. Made primarily from high-quality silicone, this type of hose balances durability and adaptability. The composition typically includes a silicone rubber that is reinforced to withstand both high temperatures and pressures, making it an ideal choice for numerous industrial and consumer uses. The inherent properties of silicone also grant this hose excellent resistance to environmental factors such as UV light and ozone, adding to its longevity.

The soft touch design of the silicone hose enhances its usability in areas requiring frequent handling or manipulation. This characteristic not only improves comfort for users but also reduces the risk of damage to surrounding components due to its cushioning effect. Furthermore, the silicone material is chemically inert, making it suitable for applications involving sensitive substances, such as food and medical industries. In summary, the combination of soft touch, robust construction, and chemical resistance makes soft touch silicone hoses a valuable asset in varied projects, providing both functionality and safety.

Soft touch silicone hoses offer a range of key properties that make them ideal for various applications across multiple industries. One of the standout features is their exceptional flexibility. This inherent flexibility allows the hoses to bend and maneuver around tight spaces, making them suitable for complicated setups in automotive, medical, and industrial environments. Additionally, the softness of the silicone surface aids in reducing friction and wear, enhancing the durability of the connected components.

Another significant property of soft touch silicone hoses is their resistance to high temperatures and extreme environmental conditions. Unlike traditional rubber hoses, these silicone counterparts can withstand a broader range of temperatures without losing structural integrity. This makes them perfect for applications involving hot fluids or gases, as well as outdoor projects exposed to varying weather conditions. Furthermore, the silicone material is inherently non-toxic and resistant to UV light, ensuring a safer and longer-lasting solution while maintaining its performance in critical applications.

| Property | Description | Benefits | Applications |

|---|---|---|---|

| Flexibility | Highly flexible and bendable structure | Allows for easy installation in tight spaces | Automotive, industrial machinery |

| Temperature Resistance | Can withstand a wide temperature range | Prevents deformation under extreme conditions | Food processing, HVAC systems |

| Chemical Resistance | Resistant to various chemicals and oils | Enhances durability and longevity | Pharmaceuticals, chemical processing |

| Soft Touch Surface | Pleasant to handle with a non-slip grip | Improves user experience and safety | Consumer products, medical devices |

| Lightweight | Significantly lighter than traditional materials | Reduces overall project weight, enhancing portability | Aerospace, portable equipment |

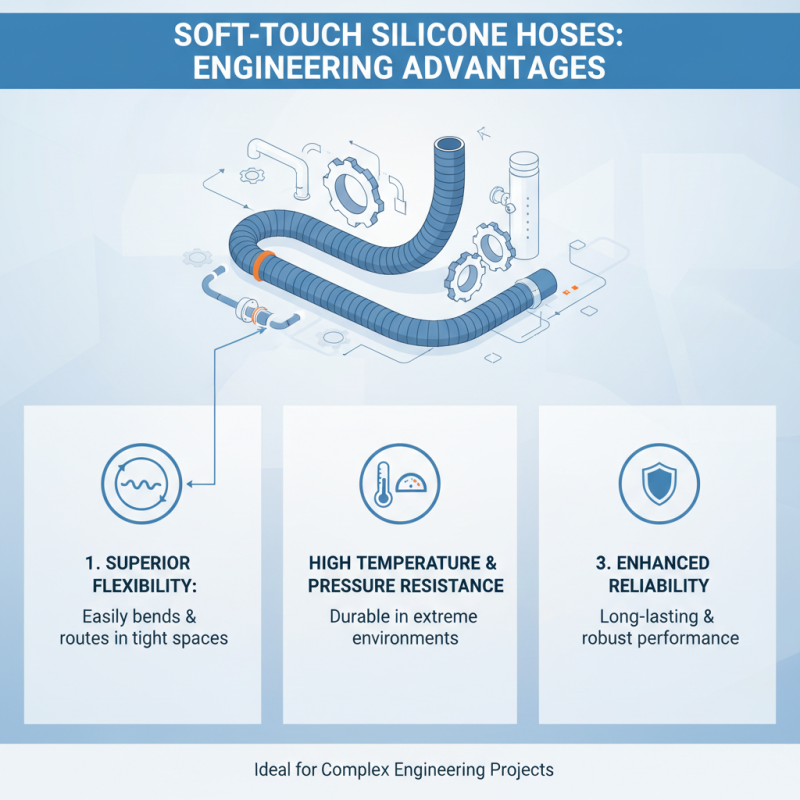

Soft touch silicone hoses have gained popularity in engineering projects due to their unique properties and numerous advantages. One of the key benefits is their superior flexibility, allowing them to bend and shape without compromising functionality. This flexibility makes them ideal for applications where space is limited or where complex routing is necessary. Furthermore, soft touch silicone hoses can withstand high temperatures and pressures, ensuring durability and reliability in demanding environments.

In addition to flexibility and resilience, soft touch silicone hoses provide excellent resistance to chemicals and aging. This characteristic greatly enhances their usability in various engineering applications, from automotive to medical equipment. Their non-reactive nature ensures that they maintain performance integrity over time, reducing the likelihood of failure or degradation.

Tips for using soft touch silicone hoses effectively include ensuring proper installation techniques to maintain the integrity of the connections. It's also recommended to regularly inspect hoses for signs of damage or wear, especially in high-stress environments. Moreover, pairing these hoses with compatible fittings can optimize their performance and longevity, making them a worthwhile investment for any engineering project.

Soft Touch Silicone Hose has gained significant traction in various industries due to its flexibility and durability. Commonly used in sectors such as automotive, food and beverage, and pharmaceuticals, these hoses are designed to withstand extreme temperature variations, offer excellent chemical resistance, and provide a non-slip grip. According to a recent industry report by MarketsandMarkets, the global silicone hose market is projected to reach USD 4.8 billion by 2026, demonstrating the rising demand for high-performance materials in industrial applications.

In automotive applications, Soft Touch Silicone Hose is frequently employed for coolant and air applications, capitalizing on its ability to maintain structural integrity under fluctuating conditions. In the food and beverage industry, these hoses are essential for conveying fluids safely and without contamination, complying with stringent health standards. Reports indicate that the food-grade silicone market is expected to grow at a CAGR of 4.1% from 2020 to 2025, highlighting the essential role of silicone hoses in ensuring safe and efficient operations.

Tip: When selecting a Soft Touch Silicone Hose, consider factors such as temperature range, pressure ratings, and compatibility with specific materials. Ensuring that the hose meets your operational needs can significantly enhance the performance of your project. Additionally, proper installation and regular maintenance can extend the lifespan of your silicone hoses, ensuring they perform optimally in demanding environments.

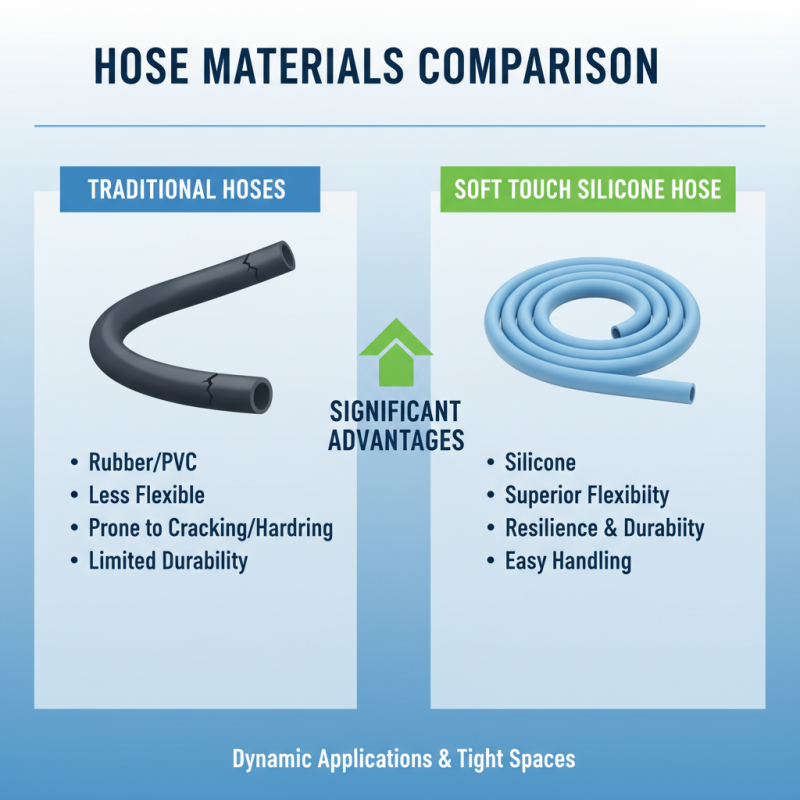

When evaluating hose materials for various projects, the comparison between Soft Touch Silicone Hose and traditional hose types reveals significant advantages. Traditional hoses, typically made from rubber or PVC, often lack the flexibility and durability required for dynamic applications. They can be more prone to cracking or hardening over time, limiting their usability in diverse environments. In contrast, Soft Touch Silicone Hose offers superior flexibility and resilience, allowing for easy handling and installation even in tight spaces.

Furthermore, Soft Touch Silicone Hose excels in thermal stability and resistance to extreme temperatures, making it ideal for both heated and cooled applications. Unlike traditional hoses that may degrade when exposed to high temperatures or chemicals, silicone hoses maintain their integrity and performance over a wide range of conditions. This feature reduces the need for frequent replacements and maintenance, ultimately saving time and costs on projects. Additionally, the soft touch design enhances user experience, as it is easier to grip and manipulate compared to conventional options. These benefits position Soft Touch Silicone Hose as a preferable choice for innovative and demanding project requirements.