When it comes to both home and industrial applications, selecting the right tools for the job is crucial, and one of the most essential components for any air system is the Rubber Air Hose. These hoses are designed to handle various tasks, from powering pneumatic tools to supplying air for spray painting and inflating tires. The versatility and durability of rubber make these hoses an ideal choice for numerous environments, whether you're working in a workshop, garage, or on a construction site.

Rubber Air Hoses are known for their resistance to wear and tear, excellent flexibility, and ability to withstand extreme temperatures and pressures. With a plethora of options available on the market, it can be overwhelming to determine which one best suits your needs. In this article, we will explore the top 10 Rubber Air Hose options, highlighting their features, benefits, and suitable applications, allowing you to make an informed decision for your air-related tasks. Whether you are a DIY enthusiast or a professional tradesperson, understanding the selection of Rubber Air Hoses will empower you to choose the perfect solution for your air compression needs.

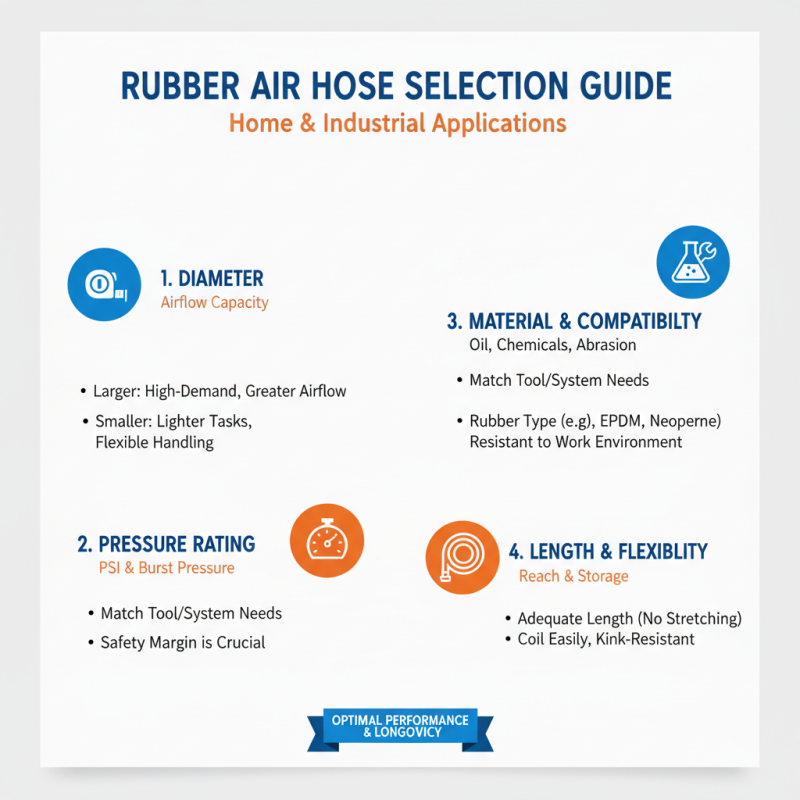

When selecting rubber air hoses for both home and industrial applications, there are several key factors to consider to ensure optimal performance and longevity. First, the hose's diameter plays a crucial role in airflow capacity. A larger diameter can facilitate greater airflow, making it suitable for high-demand tasks. Conversely, a smaller diameter may suffice for lighter applications, providing flexibility and ease of handling.

Another important consideration is the temperature and pressure ratings of the hose. Different tasks may require hoses that can withstand varying temperature conditions and pressure levels. Always check the specifications to ensure that the hose can handle the intended use without risk of damage or failure. Additionally, look for abrasion and chemical resistance if the hose will be used in rugged environments or exposed to harsh substances.

**Tips:** When purchasing a rubber air hose, consider investing in a model with a reinforced construction. This not only improves durability but also prevents kinking and tangling during use. Furthermore, checking for compatibility with existing fittings and equipment can save time and reduce the risk of leaks.

Lastly, weighing the length of the hose is essential. A longer hose provides flexibility in movement but may also lead to pressure loss over distance. Therefore, assess the workspace to determine the most practical length that balances range and efficiency.

When selecting a rubber air hose, it’s essential to focus on key features that determine quality and performance, whether for home or industrial use. One major factor is flexibility; high-quality rubber air hoses maintain their flexibility in extreme temperatures, making them easy to handle and less prone to kinks. Additionally, the durability of the hose plays a critical role. Look for products that are abrasion-resistant, as this will extend the life of the hose, especially in environments with heavy usage.

Another vital feature is the hose's burst pressure rating. A hose with a higher burst pressure can withstand intense conditions without failing, providing safety and reliability during operation. Furthermore, a smooth interior lining reduces friction loss, ensuring that air flows efficiently without significant pressure drops.

For those requiring extended reach, consider the hose length and its weight, as this can significantly affect mobility and ease of use.

Tips: When using a rubber air hose, always store it properly to avoid exposure to direct sunlight, which can degrade the material over time. Additionally, regularly check for signs of wear and tear, and replace any damaged hoses to maintain optimal performance. Finally, using compatible connectors will prevent leaks and ensure seamless operation for all your air tools.

When selecting the ideal rubber air hose for both home and industrial applications, it's crucial to conduct a thorough comparative analysis of the available options. Factors such as the hose's flexibility, durability, and pressure ratings can significantly affect performance in various settings. Most rubber air hoses feature reinforced layers to enhance their strength and resistance to wear and tear, making them suitable for high-demand environments. Look for hoses that can withstand extreme temperatures and harsh chemicals, ensuring longevity and reliability in different conditions.

Tips for choosing the right rubber air hose:

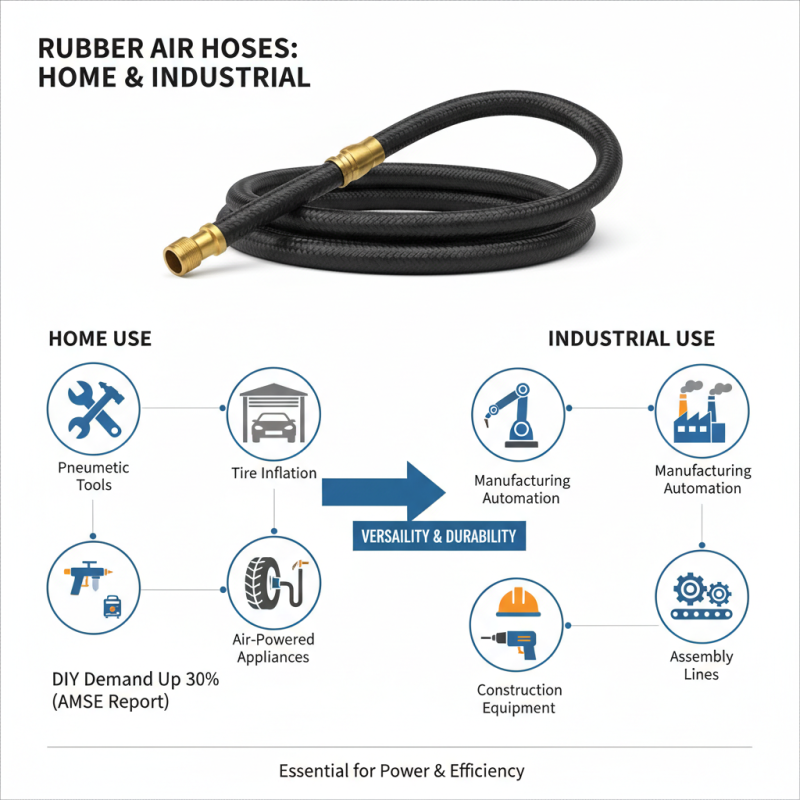

Rubber air hoses are essential tools in both home and industrial settings, providing versatility and durability for a wide range of applications. In residential scenarios, these hoses are commonly used for tasks such as powering pneumatic tools, inflating tires, and operating air-powered appliances. According to a report by the American Society of Mechanical Engineers, the demand for pneumatic tools in home workshops has surged by over 30% in recent years, making rubber air hoses an indispensable component for amateur and professional DIYers alike.

In industrial environments, rubber air hoses are crucial for streamlining operations, from manufacturing to construction sites. They are designed to withstand high pressures and extreme temperatures, ensuring consistent performance in demanding conditions. A study by the National Institute of Standards and Technology found that efficient air delivery systems, which often utilize rubber hoses, can enhance productivity by up to 25% in assembly lines. Moreover, the ability of rubber hoses to resist abrasion and chemicals makes them suitable for various applications, including painting, sandblasting, and compressed air systems. As industries continue to evolve, the reliability and performance of rubber air hoses will remain a key factor in operational efficiency.

Rubber air hoses are a vital component in both home and industrial settings, offering flexibility and durability for a variety of applications. To maximize their lifespan and ensure optimal performance, it is essential to adhere to proper maintenance practices. Regular inspection of your hoses can prevent wear and tear from escalating into serious issues. Look for signs of abrasions, cracks, or bulges, particularly at connection points where stress is most likely to occur.

Another important tip is to store rubber air hoses correctly. When not in use, coil the hose loosely and avoid sharp bends or kinks that can damage its integrity. Additionally, keeping hoses in a dry, shaded area away from direct sunlight and extreme temperatures will help retain their suppleness and prevent premature deterioration.

Finally, consider using appropriate fittings and connectors to avoid leaks and ensure a secure connection. Always check for tightness before use, as loose fittings can lead to air loss and inefficiency. By following these maintenance tips, you can extend the life of your rubber air hoses, ensuring they remain reliable tools in your toolkit.