In the world of high-performance automotive upgrades, the role of silicone hoses cannot be overstated, especially when it comes to turbo applications. Silicone hoses for turbo systems provide superior flexibility, durability, and temperature resistance compared to traditional rubber hoses. As turbochargers continue to gain popularity for increasing engine efficiency and power output, the demand for effective and reliable silicone hoses has skyrocketed. In this comprehensive guide, we will explore the top silicone hoses for turbo systems available in 2025, focusing on their performance characteristics and advantages.

When selecting silicone hoses for turbo applications, several factors come into play. Not only do these hoses need to withstand extreme temperatures and pressures, but they also must maintain optimal airflow without risking collapse or leakage. Additionally, the quality of materials used in silicone hoses contributes significantly to their longevity and effectiveness. Our selection guide will help enthusiasts and builders choose the right silicone hoses for their specific turbo setups, ensuring that they achieve the best performance while enjoying the durability that these hoses offer. Join us as we delve into the best options on the market today, setting you up for success in your automotive projects.

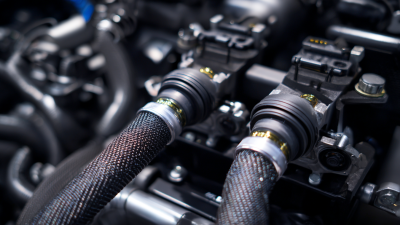

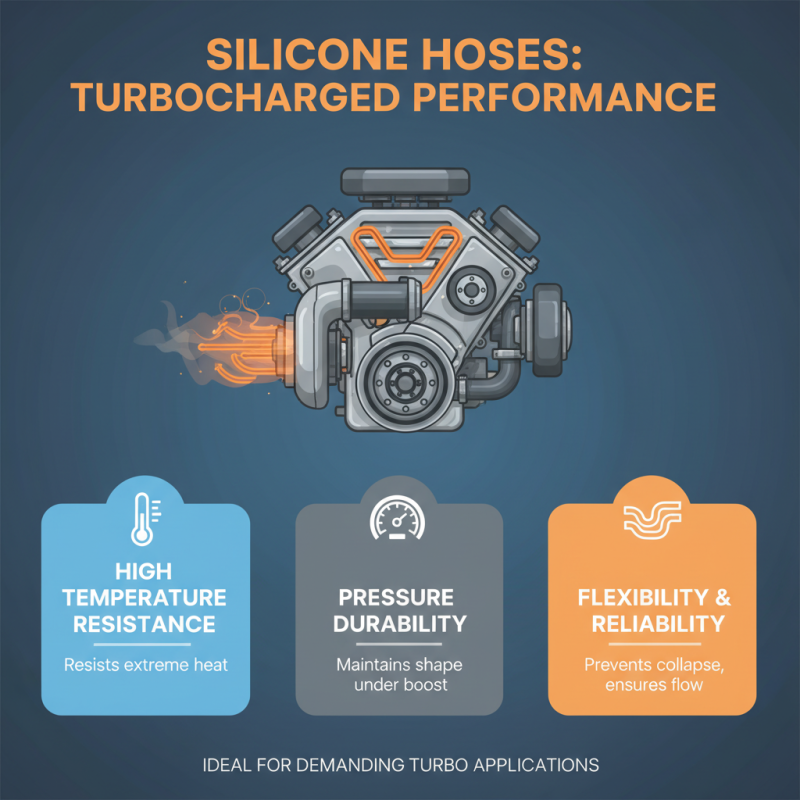

Silicone hoses have gained significant traction in turbo applications due to their exceptional performance and durability. Unlike traditional rubber hoses, silicone hoses can withstand high temperatures and pressures, making them ideal for the demanding environments found in turbocharged engines. Their ability to maintain flexibility and resist collapsing under extreme conditions ensures that they can efficiently handle the increased airflow and fluid transfer required in performance-oriented setups.

When selecting silicone hoses for turbo applications, several factors should be considered. First, the temperature rating of the hose is crucial; it should be able to operate effectively at the high temperatures generated during turbocharging. Additionally, the internal diameter of the hose must match the specific requirements of the turbo system to maintain optimal airflow and prevent any bottlenecks. The overall construction quality, including the number of plies and reinforcement types, can also influence the hose's longevity and performance; thicker and multi-ply designs typically offer enhanced pressure resistance. Overall, understanding these elements will help enthusiasts make informed choices when upgrading their turbo systems with silicone hoses.

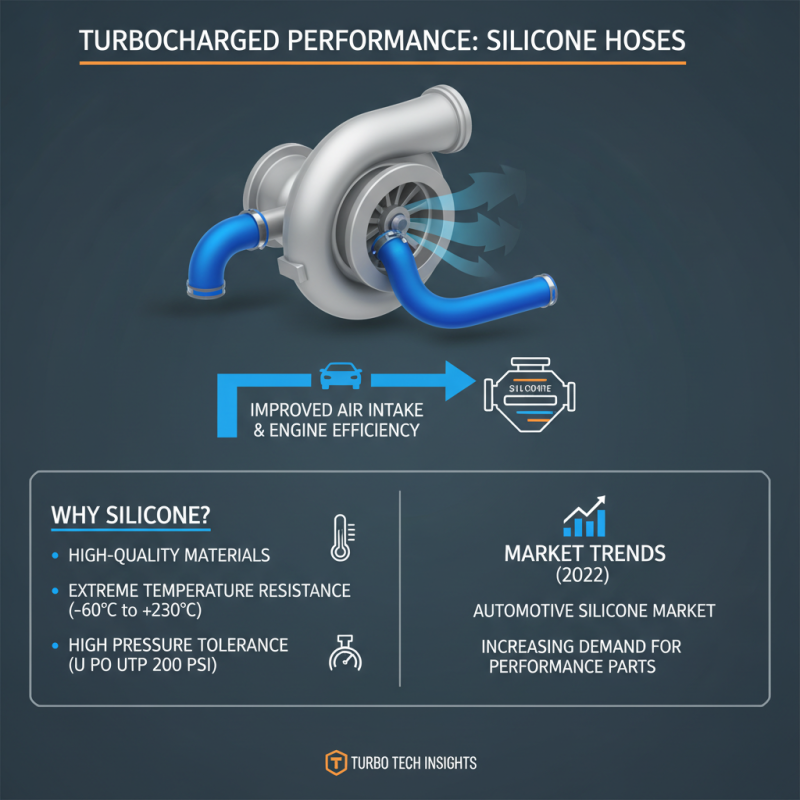

When selecting silicone hoses for turbo applications, high-quality materials and performance characteristics are paramount. According to a report by the Automotive Silicone Market Analysis in 2022, the increasing demand for performance-oriented aftermarket components has driven a significant rise in the production of silicone hoses. These hoses typically boast a higher tolerance for extreme temperatures and pressures, withstanding up to 200 psi and operating effectively in temperatures ranging from -60°C to +230°C. This is especially critical in turbocharged systems where the reliability and efficiency of air intake can affect overall engine performance.

Moreover, the key performance characteristics of high-quality silicone hoses include flexibility, tensile strength, and resistance to abrasion and ozone deterioration. Manufacturers typically report that premium silicone formulations can maintain these characteristics over time, resulting in a longer service life compared to conventional rubber hoses. The University of Michigan's Advanced Materials Research Institute highlights that silicone hoses can contribute to a 5-10% improvement in turbo efficiency, thanks to their superior airflow capabilities and reduced heat soak, which enhances engine performance. Given these factors, choosing the right silicone hose not only impacts durability but also significantly influences the performance metrics of turbocharged engines.

When it comes to turbo systems, the durability of silicone hoses is paramount for maintaining optimal performance under high-stress conditions. Several factors contribute to the longevity of these hoses, including temperature resistance, pressure tolerance, and material quality. Silicone hoses are designed to withstand extreme temperatures, which can often exceed 200°C in turbo applications. This acute resilience against thermal degradation ensures that the hoses do not crack or swell, thereby preserving their integrity and functionality over time.

Another significant factor influencing the durability of silicone hoses is the manufacturing process and the composition of the silicone itself. High-grade silicone contains additives that enhance UV stability and resistance to ozone, which are crucial for hoses that experience environmental exposure. Additionally, the reinforcement structure of the hose plays a critical role; layers of fabric or other composites can provide additional strength, preventing burst failures under pressure. Regular maintenance and proper installation also play essential roles in ensuring that the hoses operate efficiently and maintain their durability, ultimately contributing to the overall performance and reliability of turbo systems.

When selecting silicone hoses for turbo applications, several criteria should guide your decision-making process to ensure optimal performance and durability. Key factors include temperature resistance, pressure rating, and flexibility.

According to a report by the Institute of Automotive Engineering, silicone hoses can withstand temperatures ranging from -60°C to 250°C, making them suitable for high-performance environments. Their ability to maintain structural integrity under high pressure, often reaching up to 300 PSI, further emphasizes their reliability in turbo setups.

Another essential aspect to consider is the hose's construction. Multi-layer designs often provide better strength and resistance against swelling, which can lead to leaks and reduced performance. Furthermore, the silicone's durometer (hardness) plays a significant role; softer hoses can provide better sealing and flexibility, while harder hoses tend to offer increased durability and wear resistance.

Tips:

When assessing your options, factor in the compatibility of chemical substances that may come into contact with the hoses. Some silicone materials can degrade when exposed to certain fuels or oils, impacting longevity and performance. Always check manufacturer specifications for compatibility details to avoid premature failure. Additionally, consider the length and bend radius of the hose; less restrictive designs often lead to improved airflow and better turbo efficiency.

In the world of automotive performance, silicone hoses have become a quintessential component, particularly for turbocharged engines. As we delve into 2025, it's essential to highlight the top brands and products that have set the standard in silicone hose manufacturing. These hoses are engineered to withstand extreme temperatures and pressures, offering superior durability compared to traditional rubber hoses. This performance advantage is pivotal, as it ensures efficient airflow and can enhance turbo response, thereby contributing to overall engine efficiency.

When selecting silicone hoses in 2025, enthusiasts should consider factors such as construction quality, flexibility, and compatibility with various cooling systems. Leading manufacturers are known for their commitment to innovative designs and rigorous testing, ensuring that their products can handle the demands of high-performance applications. With offerings that include various sizes, colors, and forms, the market is ripe with options tailored to specific setups, giving tuners the flexibility to optimize their vehicles comprehensively. By choosing quality silicone hoses, car enthusiasts can not only bolstering their system’s performance but also enjoy the longevity and reliability these products offer under extreme conditions.

This chart displays the performance metrics of top silicone hoses for turbo applications in 2025, focusing on attributes such as Heat Resistance, Flexibility, Pressure Rating, and Service Life.