Silicone Hump Hoses have become an essential component in various automotive and industrial applications, celebrated for their durability and flexibility under high-temperature conditions. As the industry evolves, understanding the key features and benefits of silicone hump hoses is crucial for buyers looking to make informed decisions. Renowned expert in automotive engineering, Dr. Emily Grant, emphasizes the importance of quality in this market: "Investing in high-quality silicone hump hoses not only enhances performance but also ensures longevity and reliability in demanding situations."

As we explore the top silicone hump hoses for 2025, it is essential to consider factors such as material composition, heat resistance, and the specific applications for which these hoses are designed. The right silicone hump hose can significantly improve airflow and withstand the pressures of high-performance environments, making it a pivotal choice for both enthusiasts and professionals alike. In this guide, we will break down the critical features that set the best silicone hump hoses apart, providing valuable insights to help you navigate your purchasing options effectively.

When selecting silicone hump hoses, it's essential to consider their top characteristics to ensure optimal performance. One of the most critical aspects is flexibility. High-quality silicone hoses can accommodate various angles and bends without compromising airflow or causing leaks. This flexibility is crucial in applications where space is limited or where the hose must navigate complex routes within the engine or vehicle system.

Temperature resistance is another key feature of silicone hump hoses. These hoses are designed to withstand extreme temperatures, typically ranging from -60°C to 180°C (-76°F to 356°F). This temperature resilience ensures that the hoses maintain their structural integrity and functionality even under high-stress conditions, such as those found in automotive and industrial environments. Additionally, silicone's resistance to degradation from oil and other fluids enhances longevity, making it a reliable choice for various applications.

Furthermore, the strength and durability of silicone are paramount in high-performance settings. Silicone hump hoses boast superior tensile strength, allowing them to handle high pressures without rupturing. Their abrasion resistance also contributes to their longevity, as they are less susceptible to damage from external factors. These attributes are vital for maintaining optimal airflow and overall system efficiency, whether in automotive applications or other demanding environments.

| Feature | Description | Benefits | Application |

|---|---|---|---|

| Material | High-grade silicone | Resistant to extreme temperatures and pressure | Automotive and industrial applications |

| Flexibility | Designed for complex bends | Reduces stress on connection points | Intercooler and exhaust systems |

| Temperature Range | -50°C to +200°C | Safe for high-performance applications | Racing and heavy-duty machinery |

| Durability | Chemical and UV resistant | Long-lasting performance in harsh environments | Marine and off-road vehicles |

| Sizes Available | Various diameters and lengths | Customizable for different systems | HVAC and fluid transfer |

When considering the durability of silicone hump hoses, several key factors come into play. First and foremost is the quality of the silicone material used in the manufacturing process. High-grade silicone is typically more resilient to extreme temperatures and pressure variations, ensuring a longer lifespan and consistent performance under demanding conditions. Additionally, the presence of reinforcing layers, often made of nylon or polyester, can significantly enhance the hose's strength and resistance to wear and tear.

Another crucial factor influencing durability is the hose's design. Properly engineered hump hoses with smooth transitions and optimized shapes can reduce stress and turbulence, preventing premature failure. Furthermore, attention to the wall thickness is essential; thicker walls generally provide better durability but may increase weight, so a balance must be found based on the specific application. Lastly, the operating environment also plays a significant role. Hoses exposed to harsh chemicals or excessive abrasion will naturally have a reduced lifespan, underscoring the importance of selecting the right hose for the job in order to maximize durability.

When comparing silicone and traditional rubber hump hoses, several key differences come to light that affect performance, durability, and usability in various applications. Silicone hoses are often able to withstand extreme temperatures and are resistant to aging, ozone, and UV deterioration, making them ideal for high-performance environments. Traditional rubber hoses, while more cost-effective, tend to degrade faster under the same harsh conditions and may not perform well in high-temperature settings.

Tip: When choosing between silicone and rubber hoses, consider the specific demands of your application. For high-heat situations, silicone may be the more reliable choice, but for budget-sensitive projects, rubber hoses might suffice if longevity is less of a concern.

In addition to heat resilience, silicone hoses boast superior flexibility and can be molded into tighter bends without compromising their structural integrity. This flexibility can lead to a more efficient design, reducing the risk of kinking or collapsing. Rubber hoses, conversely, can be more rigid and may not offer the same versatility in pressure scenarios.

Tip: Always check the compatibility of the hose material with the fluids or gases being transferred. Silicone hoses are generally more versatile in this regard, while rubber may have specific limitations depending on the additives used.

Silicone hump hoses have become integral components in both automotive and industrial sectors due to their resilience and adaptability. In automotive applications, these hoses are primarily used in charge air systems for turbocharged engines. According to a recent industry report, silicone hump hoses can withstand temperatures ranging from -60°C to 200°C, making them significantly more effective than traditional rubber hoses in managing high-performance engine demands. Additionally, the flexibility of silicone allows for easy installation in tight spaces, which is increasingly essential as vehicles are designed to be more compact.

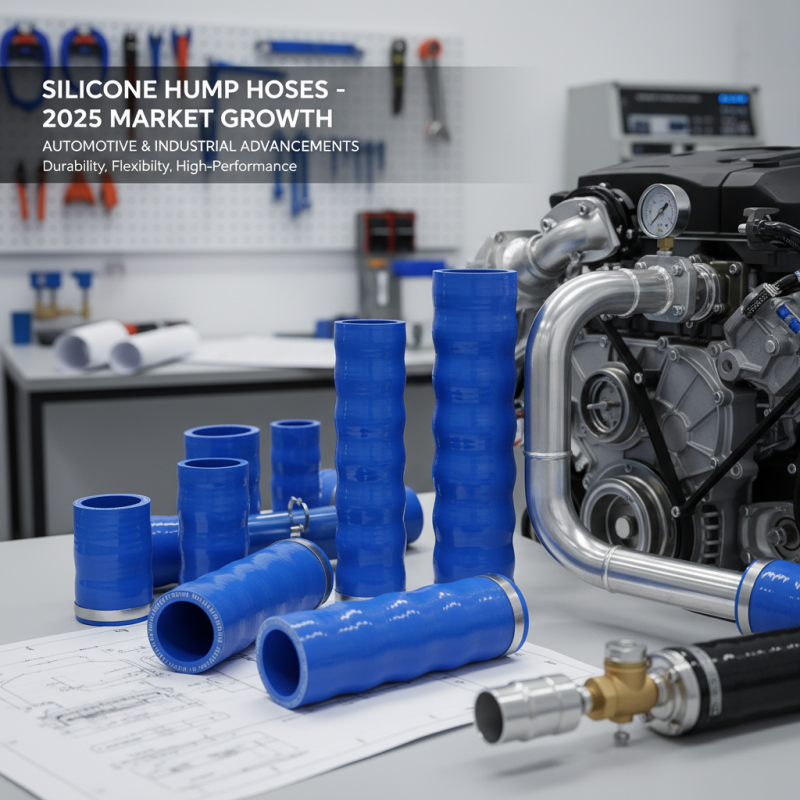

In industrial settings, silicone hump hoses are utilized in various applications, including vacuum systems, pneumatic conveying, and chemical processing. Their ability to resist abrasion and UV degradation contributes to prolonged operational life, reducing the frequency of maintenance and replacement. The global market for silicone hoses is projected to grow substantially, with an estimated increase of over 6% CAGR from 2020 to 2025, indicating an increasing reliance on these versatile components.

**Tip:** When selecting silicone hump hoses, consider the specific temperature and pressure ratings required for your application. Always check compatibility with the substances they will carry to ensure optimal performance and longevity. Another essential factor is the hose's bend radius; selecting hoses with the appropriate bend radius can prevent kinking and ensure smooth flow.

As we look ahead to 2025, the demand for silicone hump hoses is expected to see significant growth, driven by advancements in automotive and industrial applications. Silicone hump hoses are favored for their flexibility, durability, and ability to withstand a wide range of temperatures and pressures, making them a preferred choice in various systems. Market trends indicate a rising need for these hoses as industries increasingly prioritize high-performance materials that can enhance efficiency and reduce maintenance costs.

One of the key drivers of this demand is the growing electric vehicle market, which requires advanced cooling and connection systems. With a shift towards sustainable practices, manufacturers are investing in silicone products that not only meet performance standards but also align with eco-friendly initiatives. Additionally, advancements in manufacturing technologies are expected to reduce production costs, further boosting market accessibility.

Tips for buyers looking to invest in silicone hump hoses include evaluating the specific application requirements such as temperature ranges and pressure tolerances. It's also critical to consider the compatibility of the hoses with other materials in use and to look for suppliers that provide detailed product specifications and certifications. Engaging with suppliers who are knowledgeable about industry trends can also provide insights into future innovations that may affect performance and pricing.